If you’ve ever marveled at a drone executing a flawless mid-air flip, watched a robotic arm assemble a circuit board with surgeon-like precision, or even held a smartphone that stabilizes shaky videos, you’ve witnessed the magic of micro servos. These miniature motors, often no larger than a sugar cube, are the invisible force driving today’s most cutting-edge innovations. But what makes them so revolutionary? Let’s peel back the layers.

The Birth of Small Wonders

The story of micro servos begins in the mid-20th century, when engineers first miniaturized servo mechanisms for military and aerospace applications. Early versions were clunky, power-hungry, and expensive. Fast-forward to the 21st century: advancements in materials science, microelectronics, and manufacturing techniques transformed these devices into affordable, efficient powerhouses. Today’s micro servos pack torque, speed, and programmability into packages small enough to fit inside a child’s toy—or a life-saving medical implant.

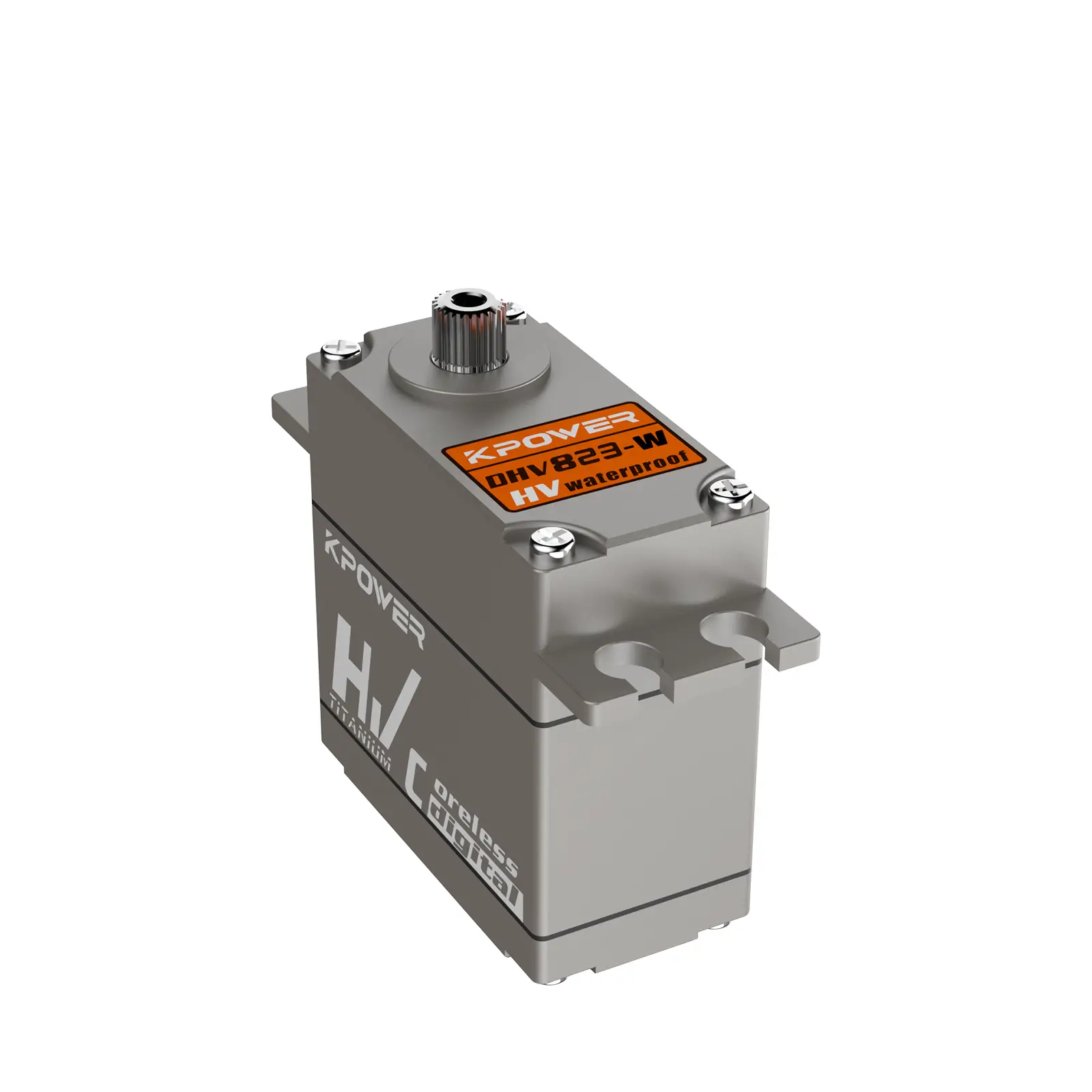

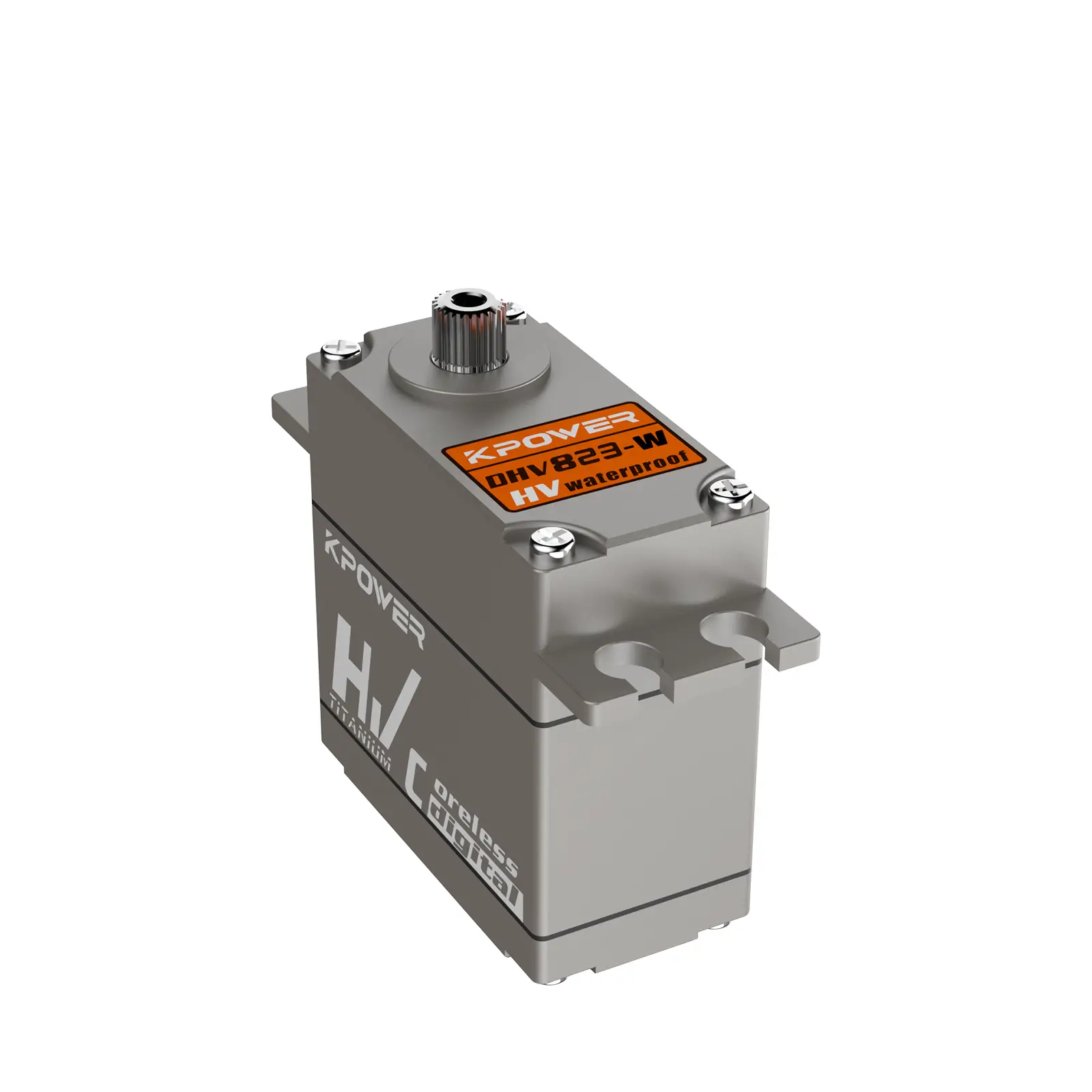

Anatomy of a Micro Servo

At their core, micro servos consist of three key components:

A miniature DC motor for raw rotational power. A gearbox to amplify torque while reducing speed. A control circuit that interprets electronic signals to adjust position or speed.

What sets them apart is feedback control. Using sensors like potentiometers or encoders, micro servos self-correct in real time, ensuring precise movement—whether they’re adjusting a camera lens or mimicking human finger movements in a bionic hand.

From Hobbyists to Heroes: Everyday Applications

Micro servos aren’t confined to labs or factories. They’re everywhere:

Consumer Tech: Smartphone cameras use micro servos for optical image stabilization, ensuring crisp photos even in motion. Robotics: From Roomba vacuums to Boston Dynamics’ Spot, servos provide agility and adaptability. Healthcare: Prosthetic limbs and surgical robots rely on micro servos for lifelike motion and accuracy. DIY Culture: Makers and hobbyists embed them into custom drones, animatronic props, and even coffee-making robots.

Take the example of drone racing. Pilots depend on micro servos to adjust control surfaces mid-flight, enabling split-second maneuvers at speeds over 80 mph. Without these components, the sport—and industries like aerial cinematography—wouldn’t exist.

The Quiet Revolution in Automation

In industrial settings, micro servos are redefining efficiency. Traditional assembly lines used bulky pneumatic systems, but micro servos offer finer control with less energy. A factory producing smartwatches, for instance, might use hundreds of micro servos to place microscopic components onto circuit boards—tasks too delicate for human hands.

But it’s not just about speed. Micro servos enable collaborative robots (“cobots”) to work safely alongside humans. Equipped with torque sensors, these cobots can sense resistance (like a human arm in their path) and instantly adjust their force, reducing workplace injuries.

Challenges and Limitations

For all their brilliance, micro servos aren’t flawless. Heat dissipation remains a hurdle in high-performance applications, and their plastic gears can wear out under constant stress. Yet innovators are already tackling these issues. Companies like Dynamixel are experimenting with metal-alloy gears and liquid cooling, while open-source projects push the boundaries of servo programming.

The Next Frontier: AI and Micro Servos

Imagine a future where micro servos don’t just follow pre-programmed commands but learn from their environment. With machine learning algorithms, servos could adapt to unpredictable scenarios—like a delivery drone navigating sudden wind gusts or a prosthetic hand “feeling” textures. Startups like OpenAI and Boston Dynamics are already integrating AI with servo systems, creating machines that improvise and problem-solve in real time.

Sustainability Meets Precision

As climate change reshapes industries, micro servos are playing a surprising role in sustainability. Wind turbines use micro servos to adjust blade angles for optimal energy capture, while precision agriculture systems employ them to control irrigation valves, reducing water waste. Even the fashion industry is getting creative: designers are embedding micro servos into adaptive clothing that adjusts fit based on the wearer’s movements.

The Rise of Biohybrid Systems

One of the most exciting frontiers is the fusion of micro servos with biology. Researchers at institutions like MIT and ETH Zurich are developing biohybrid robots that combine living tissue with synthetic actuators. For instance, a robotic stingray powered by rat heart cells uses micro servos to simulate swimming motions. These breakthroughs hint at a future where medical micro-robots, guided by servos, could deliver drugs directly to cancer cells or repair damaged nerves.

Empowering the Maker Movement

Affordable micro servos (some costing less than $10) have democratized innovation. Platforms like Arduino and Raspberry Pi let anyone build custom projects—from robotic bartenders to solar-tracking garden lights. Online communities share blueprints for 3D-printed servo mounts and code snippets for complex movements. This accessibility is fostering a new generation of inventors, blurring the line between professional engineers and weekend tinkerers.

Ethical Dilemmas and the Path Forward

With great power comes great responsibility. Micro servos in autonomous weapons or surveillance drones raise ethical questions. However, the focus remains on positive applications. Engineers are prioritizing safety features, like fail-safes that disable servos if a drone loses signal, and advocating for open-source designs to prevent monopolies.

Conclusion: Small Parts, Big Dreams

Micro servos are more than components—they’re enablers of human ambition. They turn sci-fi concepts into everyday tools, empower individuals to innovate, and quietly push the boundaries of what’s possible. As nanotechnology and AI evolve, these tiny titans will continue to shape industries we haven’t even imagined yet. The next time you see a robot dance, a drone soar, or a prosthetic hand grasp a cup, remember: inside that marvel of engineering, a micro servo is working tirelessly, proving that size has nothing to do with impact.

This concludes the two-part exploration of micro servos. Whether you’re an engineer, a hobbyist, or simply curious, one thing’s clear: the future is small, and it’s moving faster than ever.