Imagine a tiny miracle working silently behind the scenes—an unassuming component with the power to transform the way machinery operates. Enter the worm gear motor, a marvel of engineering that combines the simplicity of its design with the sophistication of its performance. Specifically, the 6 RPM variant exemplifies this balance perfectly, offering users a unique blend of high torque, low speed precision, and quiet, vibration-free operation.

The Essence of Worm Gear Motors

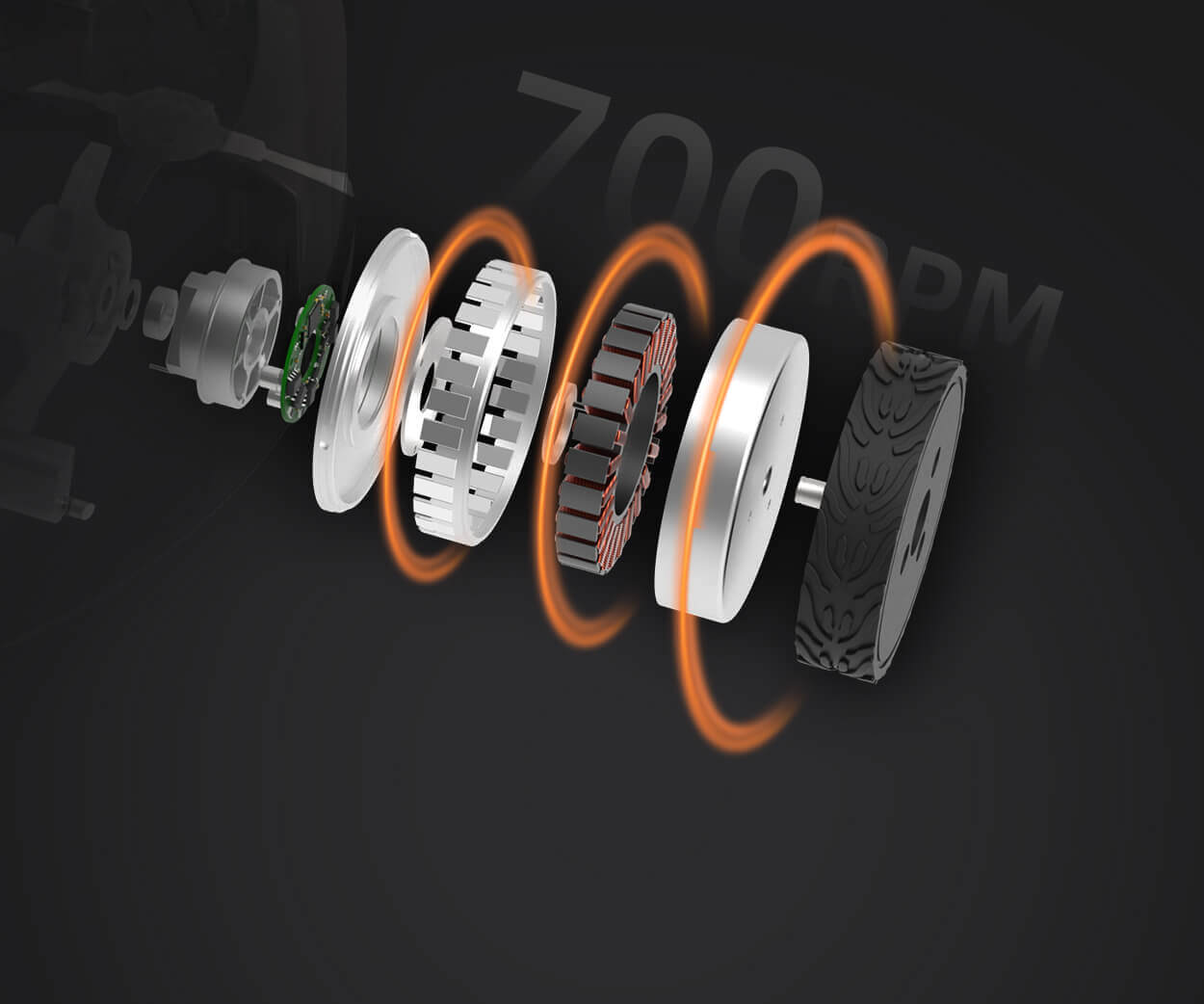

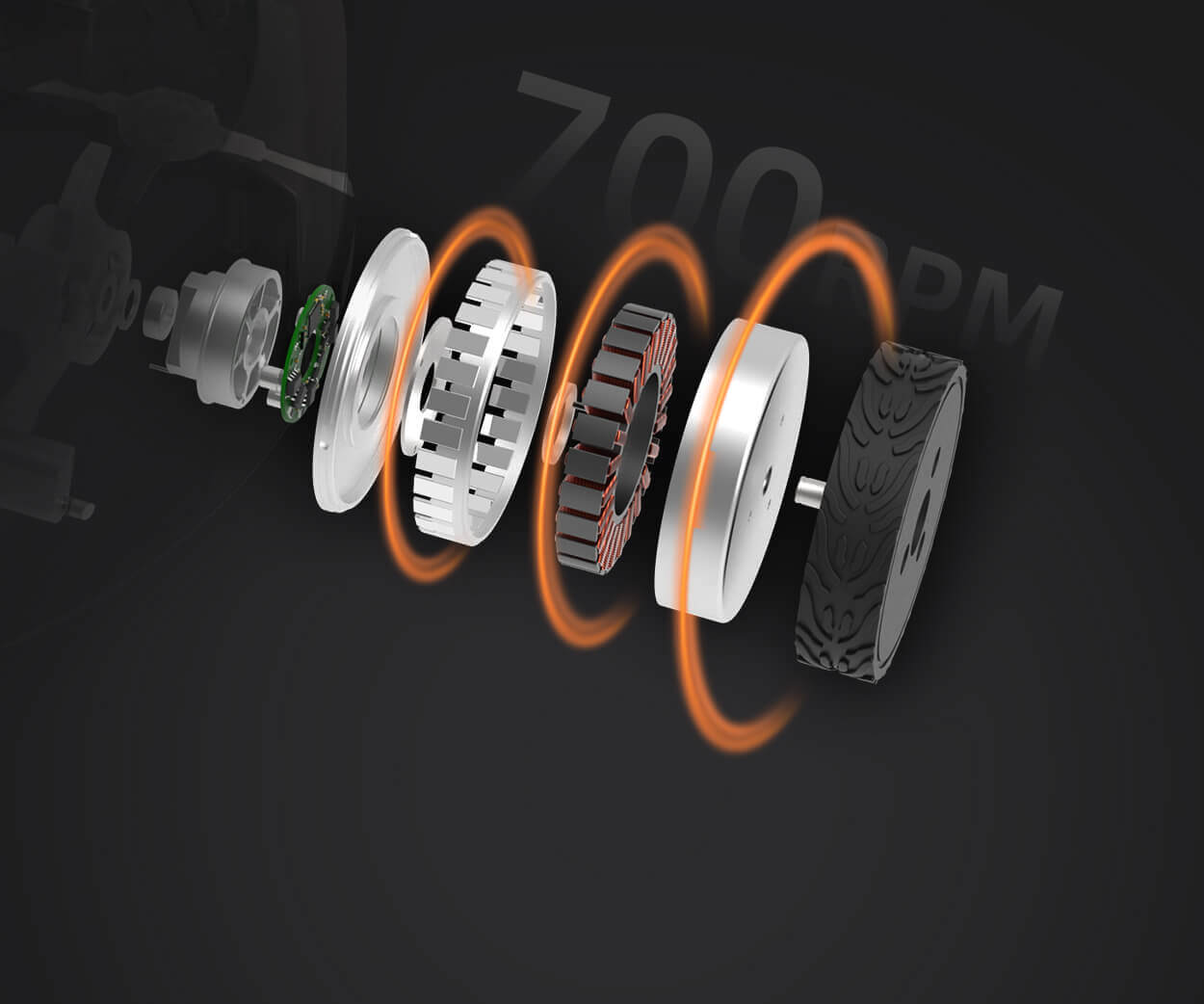

Worm gear motors are a specialized type of gear reduction device that pair a worm (a screw-like gear) with a worm wheel (similar to a gear) to transmit power. Unlike traditional gear systems, worm gear drives are particularly celebrated for their ability to achieve significant speed reduction within compact spaces—a feature that makes them especially invaluable across industries.

At their core, these motors serve as both the power source and the reducer, often integrated into a single unit. The combination leads to an efficient transfer of motion, with the added advantage of unique directional control: the worm can turn the gear, but the gear cannot turn the worm. This one-way power transmission is why worm gear motors are often used for applications requiring precise torque control and holding mechanisms.

Why Choose a 6 RPM Worm Gear Motor?

While worm gear motors come in various speeds and power ratings, the 6 RPM models stand out for their ability to deliver extremely low, controlled rotational speeds. Operating at just 6 revolutions per minute, these motors are designed for applications where slow, deliberate movements are crucial. Think of them as the steady hands guiding delicate processes—balancing power with precision.

This low RPM rating translates into several benefits:

High Torque Output: The gear reduction amplifies torque, enabling the motor to move loads that are otherwise hard to control at higher speeds. Enhanced Precision: Maintaining a slow, stable motion is vital in scenarios requiring accuracy, such as automation, robotics, and instrumentation. Quiet Operation: The gentle, steady rotation minimizes vibrations and noise, making these motors ideal for environments where silence and smoothness are valued. Energy Efficiency: Despite their slow speed, worm gear motors often operate with low energy consumption while delivering consistent performance.

The Science Behind the Speed

Achieving 6 RPM isn’t merely about slowing down the motor; it’s about leveraging ingenious gear ratios. In essence, the worm gear system is designed with a high gear ratio—say, 60:1 or even higher—meaning the motor spins much faster, but through the gear mechanism, the output shaft turns slowly.

This gear ratio flexibility allows manufacturers to tailor the motor to specific needs. For instance, a 1 RPM motor can be achieved by an even higher gear ratio, but 6 RPM often hits the sweet spot for many industrial applications—slow enough for precision, yet sufficient torque for practical functionality.

Applications Where a 6 RPM Worm Gear Motor Shines

The versatility of worm gear motors at 6 RPM extends across numerous industries and applications:

Industrial Conveyors & Lifts: Gentle, controlled movement of heavy loads or delicate items. Robotics & Automation: Precise positioning of robotic arms or components requiring slow, steady motion. Camera & Telescope Mounts: Fine adjustments in orientation without jitter. Medical Devices: Gentle movements in equipment like surgical tables or diagnostic machinery. Agricultural Machinery: Accurate control of seed planting or irrigation mechanisms.

In all these scenarios, the key advantage lies in the motor’s ability to maintain a consistent, reliable, low-speed operation with high torque—something few other motors can accomplish with such finesse.

Design & Construction: Building Blocks of Efficiency

The durability and efficiency of a worm gear motor are rooted in its design:

Worm and Worm Wheel Materials: Often constructed from high-strength steel or bronze, these materials are selected for their durability and low wear, ensuring longevity even under heavy loads. Lubrication: Proper lubrication reduces friction, prolonging life and maintaining smooth operation over time. Compact Construction: Their integrated design makes them space-efficient, fitting into tight spaces where other gear systems might not.

Maintenance & Troubleshooting Tips

To keep a worm gear motor at peak performance, regular maintenance is advised:

Check lubrication levels periodically and reapply as specified. Inspect for signs of wear or damage on gears. Ensure the motor is operating within its rated load and temperature limits to prevent overheating. Keep the motor clean and free from dust or debris that could impair performance.

Part One Wrap-Up

A worm gear motor operating at 6 RPM may seem modest at first glance, but don’t let its calm exterior fool you. This compact powerhouse delivers unparalleled control, torque, and reliability—attributes that are transforming industries and powering innovative solutions worldwide. Whether it’s guiding a robotic arm with millimeter precision or lifting loads smoothly and silently, the 6 RPM worm gear motor continues to prove its worth as a cornerstone of modern engineering.

Kpower has delivered professional drive system solutions to over 500 enterprise clients globally with products covering various fields such as Smart Home Systems, Automatic Electronics, Robotics, Precision Agriculture, Drones, and Industrial Automation.