Unlocking Power and Precision: The Marvel of DC Worm Geared Motors

In the dynamic world of industrial machinery and automation, the quest for efficient, reliable, and precise motion control solutions has led engineers and designers to explore a variety of motor technologies. Among these, DC worm geared motors stand out as a remarkable blend of simplicity, durability, and versatility, making them a popular choice across countless applications.

The Basics of DC Worm Geared Motors

At their core, DC worm geared motors combine a standard direct current (DC) motor with a worm gear drive. This union converts electrical energy into mechanical motion, but with a unique feature: the worm gear's design provides a high reduction ratio, translating into significant torque multiplication and speed reduction. This means a small, efficient motor can drive loads requiring much higher force, all within a compact form factor.

The worm gear mechanism involves a screw-like gear (the worm) engaging with a gear wheel (the worm wheel, or gear). When the worm turns, it drives the worm wheel, producing rotary motion. Notably, this setup offers a one-way drive mechanism—ideal for applications that require holding a position without power, thanks to the self-locking nature of many worm gears.

Design and Construction

DC worm geared motors are built with durability and precision in mind. The typical design features a robust housing—often cast iron or aluminum—that shields internal components from dust, moisture, and mechanical shocks. Inside, the DC motor is coupled directly or via a shaft to the worm gear assembly.

The worm gear itself is crafted from hardened steel, bronze, or other wear-resistant materials to withstand repetitive motion and heavy loads. The gear ratio can vary widely—from low ratios like 4:1 to ultra-high ratios exceeding 100:1—tailored to specific application requirements.

Functionality and Performance

One key characteristic of these motors is their remarkable torque output relative to size. Due to the gear reduction, even a small motor can generate significant turning forces, making them ideal for applications where strong, controlled movement is needed in a compact space.

Another notable feature is their self-locking capability—when the motor is powered down, the gear can resist back-driving forces. This makes them an excellent choice for lifting, positioning, and holding applications, where power consumption should be minimized once the desired position is achieved.

Efficiency is also enhanced by the design—the gearboxes often improve the overall power transfer, reducing energy wastage and heat buildup. The motor's simplicity and the gear mechanism's robustness mean lower maintenance and longer service life, critical factors for industrial users.

Advantages over Other Motor Types

While AC motors or other types of gear motors have their place, DC worm geared motors offer specific benefits that set them apart:

High Torque at Low Speeds: Ideal for applications requiring precise and powerful control, such as conveyor systems or lifting mechanisms. Self-Locking Property: This inherent feature eliminates the need for additional brakes in many scenarios, simplifying design and reducing costs. Compact and Space-Efficient: Their integrated design allows for installation in tight spaces without sacrificing performance. Cost-Effective Operation: Lower maintenance costs and high efficiency reduce long-term operational expenses. Flexible Gear Ratios: Customizable gear ratios enable tailoring performance to specific needs.

Industrial Applications

DC worm geared motors are found everywhere, from small robotics projects to large industrial machinery. Here's a glimpse into their diverse applications:

Material Handling and Conveyors: Their high torque and holding capacity make them perfect for lifting and positioning loads. Lifting Equipment: Cranes, hoists, and other lifting solutions leverage their self-locking ability to maintain positions securely. Automated Gates and Doors: Precise control and holding power help in smoothly operating large gates and sliding doors. Robotics: For controlled movements where space and power are limited, worm geared motors provide reliable solutions. Printing Machines: Precise, repeatable motion is essential, and their stability offers an advantage.

Choosing the Right DC Worm Geared Motor

When selecting a worm geared motor, several factors influence the decision:

Torque Requirements: Determine the load and the force needed to perform the task effectively. Speed Range: Match available gear ratios to your application's speed control needs. Power Supply Compatibility: Ensure the motor's voltage and current ratings align with your power source. Environmental Conditions: If operating in harsh environments, select motors with suitable sealing and corrosion resistance. Size Constraints: Space limitations may dictate motor dimensions.

By carefully balancing these factors, users can unlock the full potential of DC worm geared motors and optimize their machinery’s performance.

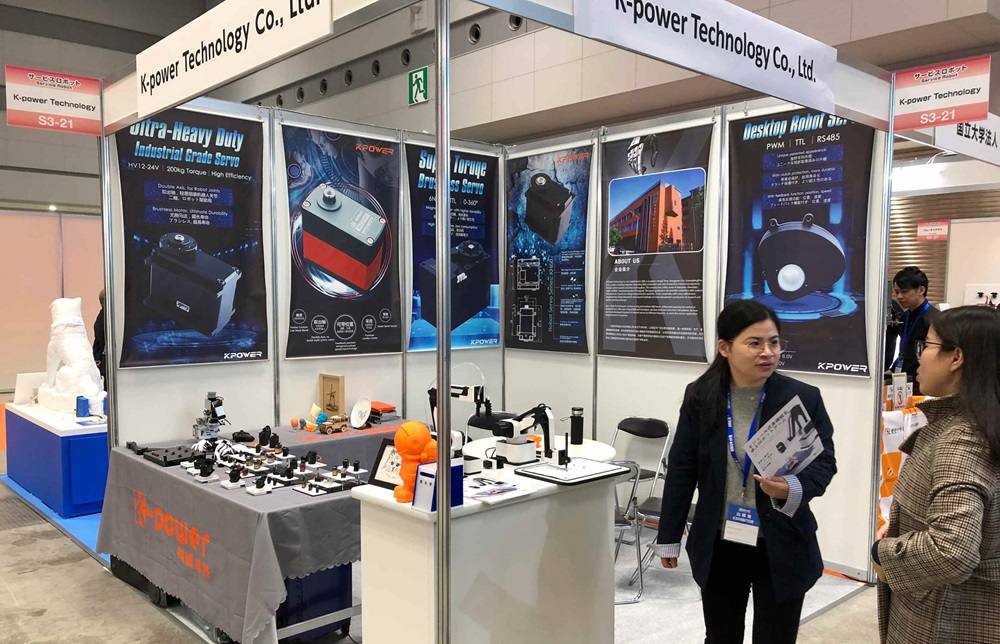

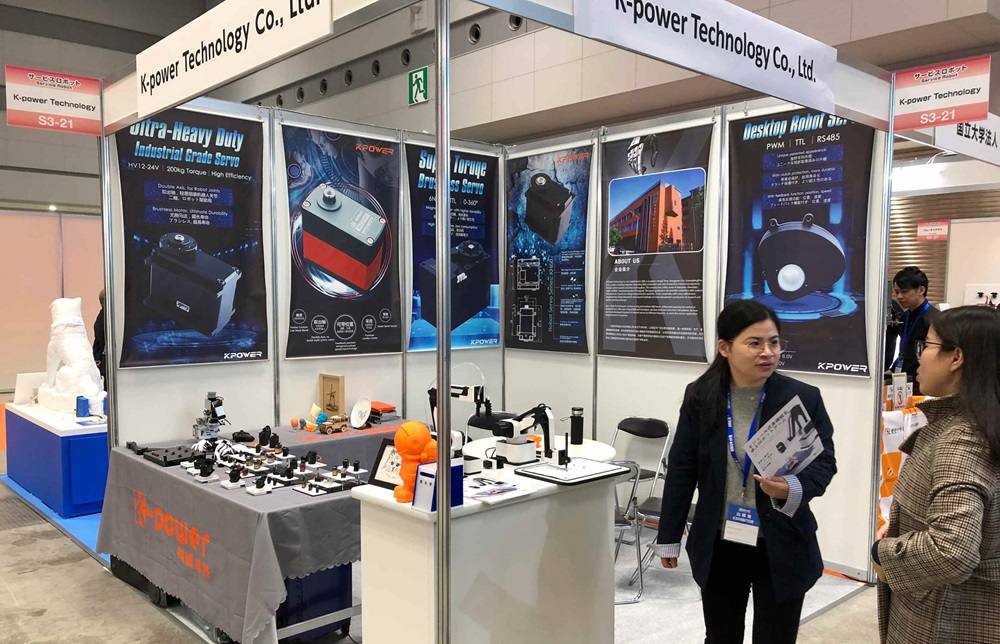

Established in 2005, Kpower has been dedicated to a professional compact motion unit manufacturer, headquartered in Dongguan, Guangdong Province, China.