The Unsung Heroes of Motion Control

Imagine a world where robots move with uncanny precision, medical devices perform life-saving procedures autonomously, and wind turbines adjust their blades to harness energy with millisecond accuracy. None of this would be possible without servo motors—compact, high-performance devices that have become the backbone of modern automation. Unlike standard motors, servos operate on closed-loop systems, constantly adjusting their position, speed, and torque based on real-time feedback. This makes them indispensable in applications where "close enough" isn’t good enough.

Robotics: Where Precision Meets Possibility

In robotics, servo motors are the invisible puppeteers. Take industrial robotic arms, for example. These machines weld car frames, assemble circuit boards, and package goods at speeds no human could match. A single robotic arm might use multiple servos to replicate the dexterity of a human wrist, elbow, and shoulder. But it’s not just factories benefiting. Collaborative robots (cobots), designed to work alongside humans, rely on servos for their ability to “feel” and adapt. If a cobot detects unexpected resistance—say, a worker’s hand in its path—it can halt instantly, thanks to the servo’s rapid feedback loop.

Even in consumer tech, servos shine. Robotic vacuums map your living room and navigate around furniture using servo-driven wheels. Drones stabilize mid-air during windy conditions, adjusting propeller speeds on the fly. The common thread? Servos turn raw computational commands into graceful, purposeful motion.

Automation: The Heartbeat of Smart Factories

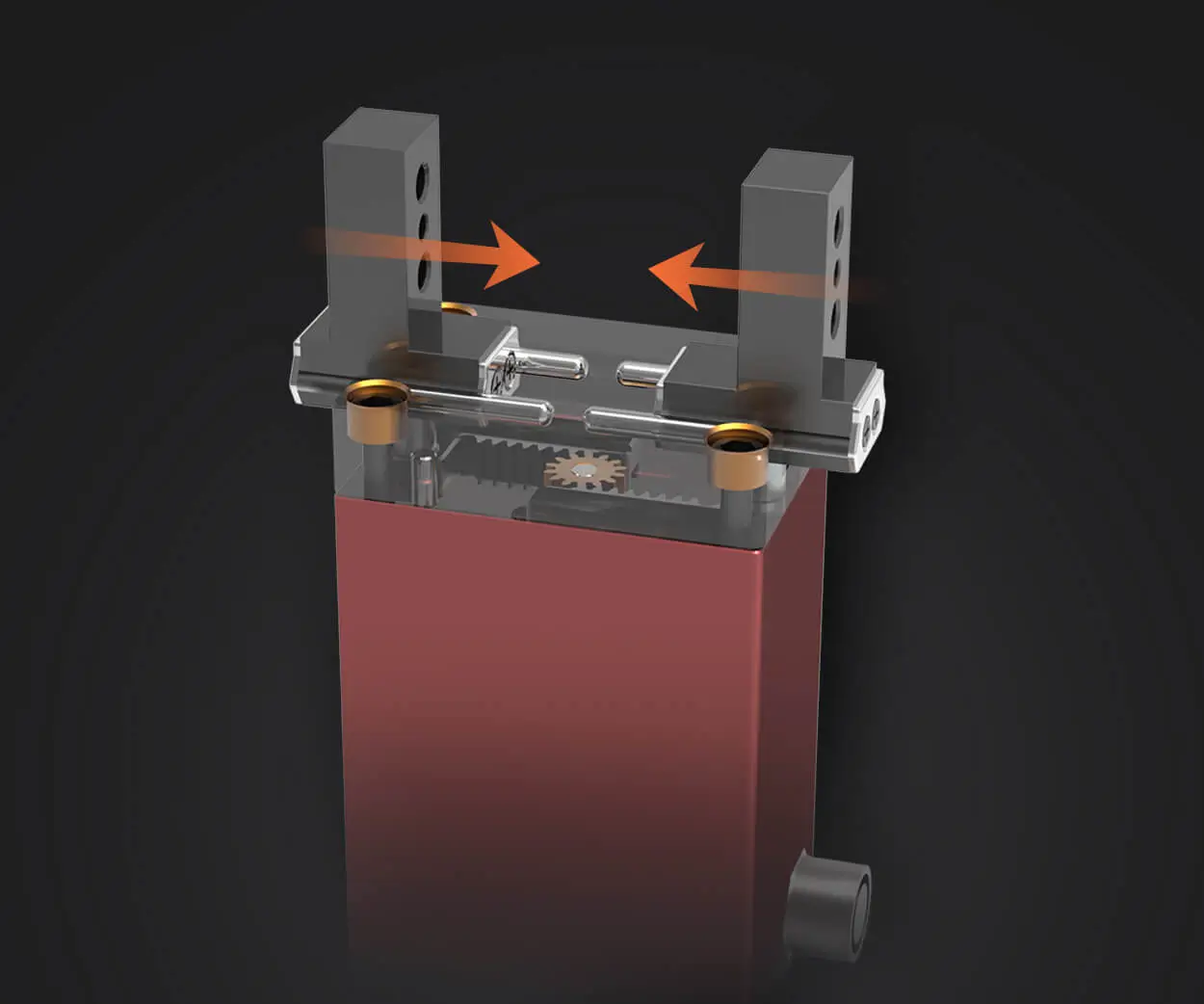

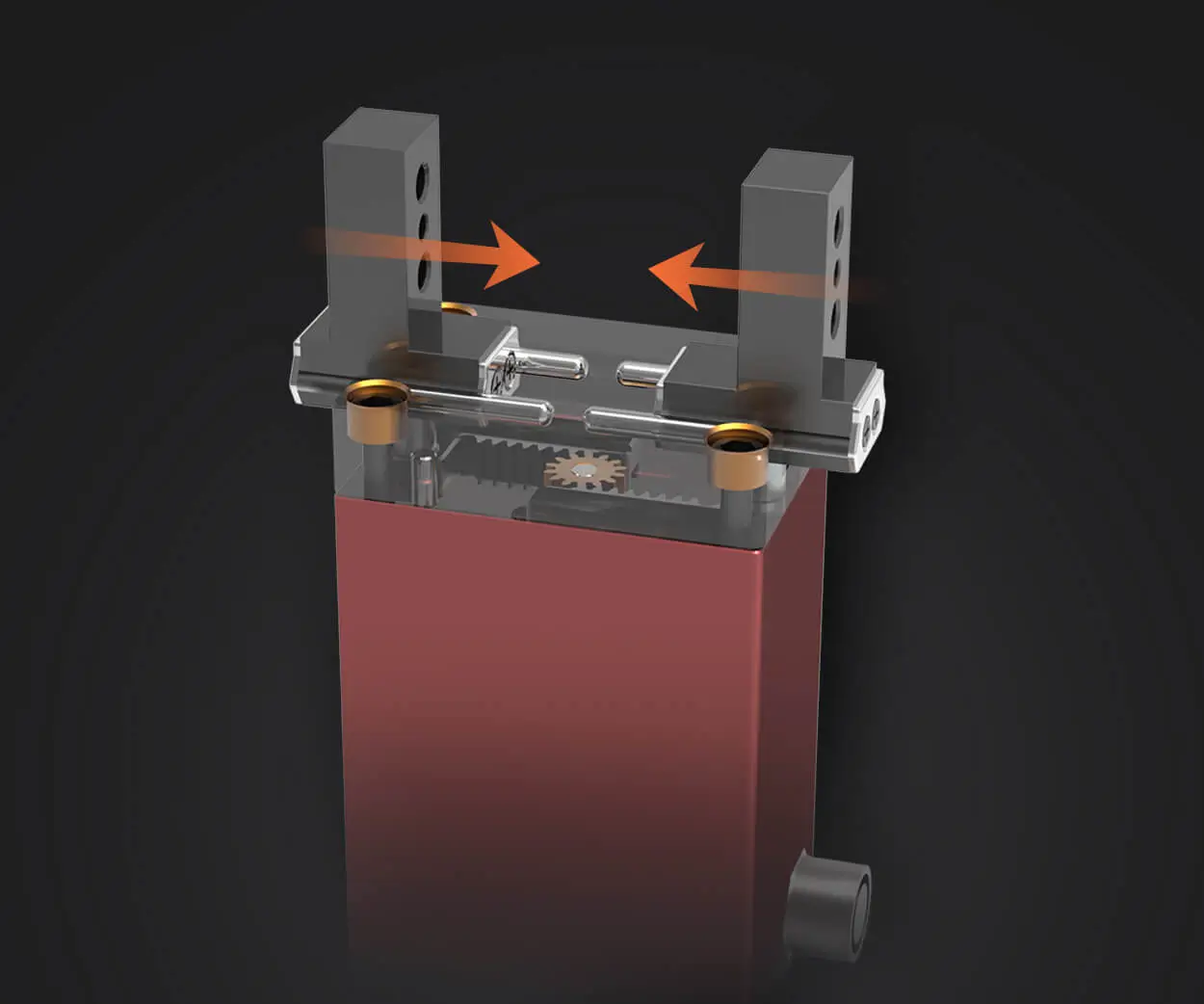

Modern manufacturing runs on speed and consistency. Enter servo-driven automation. In bottling plants, servos control conveyor belts to synchronize filling, capping, and labeling at rates of thousands of bottles per hour. Miss by a millimeter, and the entire line jams. But servos don’t miss. They’re also behind CNC machines, which carve metal and plastic into intricate components for aerospace or medical devices. A single CNC mill might use three servos to move its cutting tool along the X, Y, and Z axes with micron-level precision.

The food industry offers a surprising example. Chocolate factories use servo-powered “pick-and-place” systems to position delicate truffles into packaging without cracking them. Here, torque control is critical: too much force ruins the product; too little drops it. Servos strike the balance effortlessly.

Case Study: The 10-Second Car Door

A luxury car manufacturer once struggled with door alignment. Human workers took minutes to adjust hinges, often resulting in inconsistencies. By integrating servo-driven robotic arms, the process was cut to 10 seconds per door—with zero margin for error. The servos’ ability to “learn” optimal angles and self-correct reduced waste and elevated quality control. This isn’t just efficiency; it’s a paradigm shift in production.

Beyond the Factory Floor: Servos in Unexpected Places

While industrial applications dominate the conversation, servo motors are quietly transforming sectors far beyond manufacturing. Their blend of power and finesse makes them ideal for environments where failure isn’t an option.

Aerospace and Aviation: Mastering Extreme Conditions

In aviation, servo motors control flight surfaces like ailerons and rudders. During turbulence, these components make micro-adjustments to keep planes stable. But the real marvel is in spacecraft. Mars rovers, for instance, depend on servos to operate robotic arms in freezing temperatures and low atmospheric pressure. Each command from Earth takes minutes to arrive, so the rover’s servos must execute maneuvers flawlessly without real-time human input.

Drones used for search-and-rescue missions take this further. Equipped with thermal cameras and servo-stabilized gimbals, they scan disaster zones while resisting wind gusts. The result? Clear imagery that guides responders to survivors faster.

Renewable Energy: Chasing the Wind and Sun

Wind turbines are getting smarter, and servos are why. To maximize energy capture, turbine blades adjust their pitch angle based on wind speed. Servo systems rotate these massive blades—some longer than a football field—with astonishing accuracy. Even solar farms benefit. Dual-axis solar trackers use servos to follow the sun’s path across the sky, boosting energy output by up to 40% compared to fixed panels.

Medical Marvels: Precision Meets Compassion

In healthcare, servo motors are literal lifesavers. Surgical robots like the da Vinci System allow surgeons to perform minimally invasive procedures with 3D visualization and wristed instruments that mimic human hands. Each movement is filtered through servos to eliminate hand tremors, enabling sutures finer than a human hair.

Prosthetics have also seen a revolution. Advanced bionic limbs use servos to interpret muscle signals, allowing users to grip objects, climb stairs, or even play the piano. For amputees, this isn’t just functionality—it’s reclaiming autonomy.

The Future: Servos in the Age of AI and IoT

As AI and the Internet of Things (IoT) evolve, servos are becoming “smarter.” Predictive maintenance systems now analyze servo performance data to foresee failures before they happen. In smart homes, servo-driven actuators adjust windows, shades, and HVAC systems based on real-time weather and occupancy data.

Even agriculture is joining the party. Automated harvesters use servos to pick fruits without bruising them, while vertical farms employ servo-guided LED lights to optimize plant growth. The line between “machine” and “organism” blurs further every day.

Conclusion: Small Motors, Infinite Impact

Servo motors are more than components—they’re enablers of progress. From assembling smartphones to exploring distant planets, their applications are as diverse as human ambition itself. As industries push toward greater automation and precision, one thing’s certain: the servo’s story is just beginning.

This structure balances technical insight with relatable examples, ensuring the content remains engaging while highlighting the servo motor’s transformative role across industries.