Imagine a world where robots the size of your palm can lift objects, rotate with precision, and execute complex movements—all thanks to a component smaller than a matchbox. Enter the micro servo 9g S51, a powerhouse of engineering that’s quietly revolutionizing everything from hobbyist drones to advanced prosthetics. But what makes this tiny device so extraordinary? Let’s peel back the layers of its datasheet and uncover the magic.

The Anatomy of Miniature Might

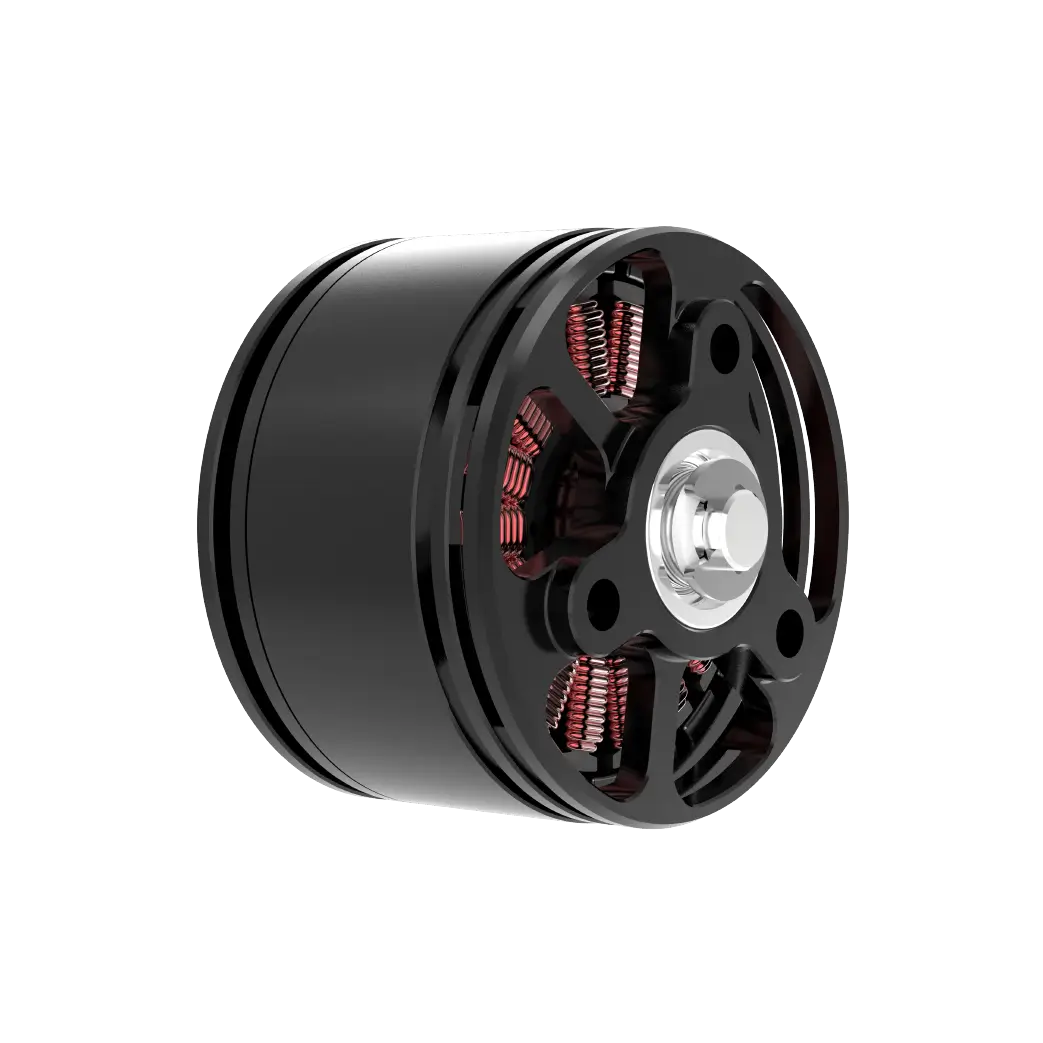

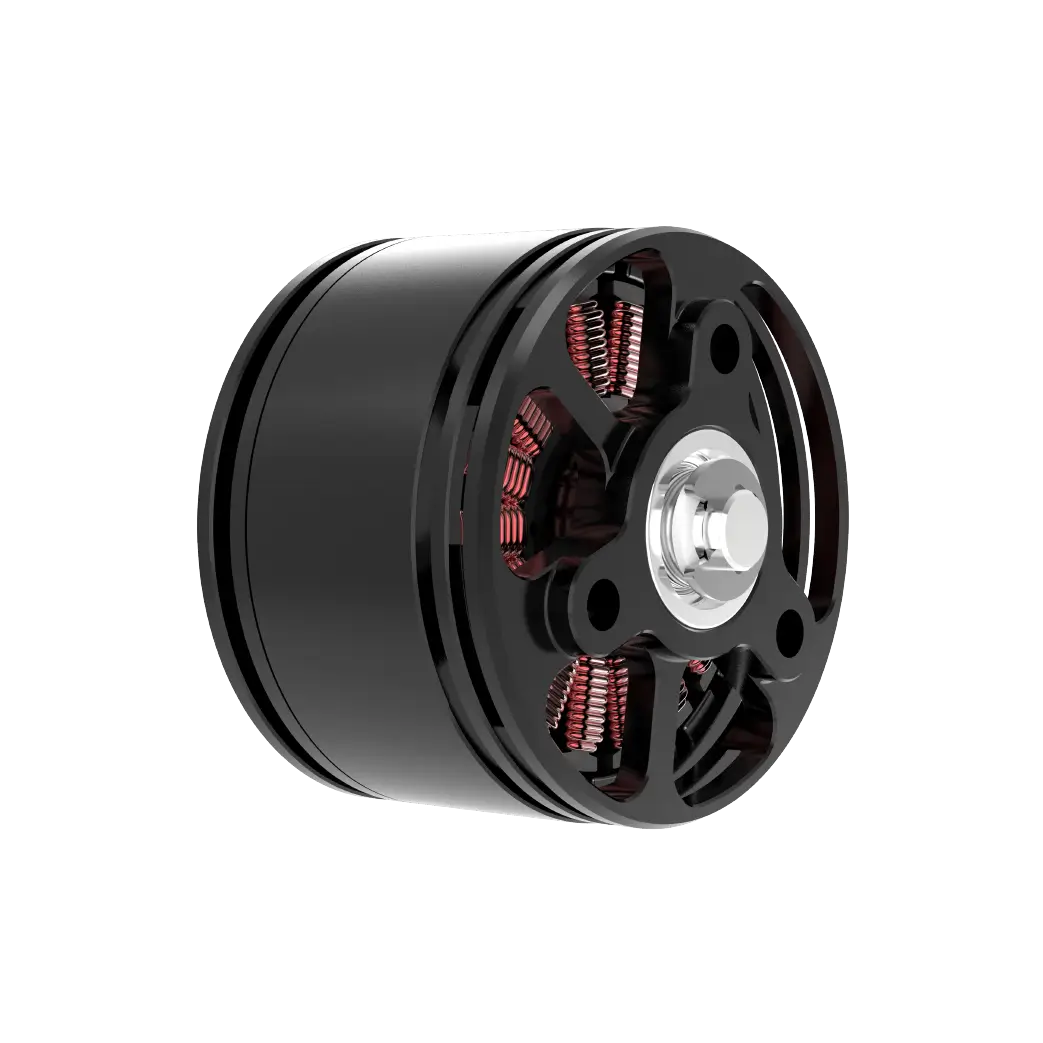

At first glance, the S51’s compact dimensions (22.2 x 11.8 x 24 mm) and featherlight 9-gram frame might make it easy to overlook. But within its plastic shell lies a meticulously designed system: a DC motor, gear train, potentiometer, and control circuitry. The datasheet reveals a torque range of 1.2–1.6 kg·cm, which sounds abstract until you picture it effortlessly rotating a small camera mount or adjusting the flap of a model airplane mid-flight. Its operating voltage (3.0–6.0V) means it’s compatible with most DIY setups—no bulky power supplies required.

What truly sets the S51 apart is its speed. Clocking in at 0.10–0.12 seconds per 60 degrees, it’s nimble enough for real-time responsiveness. For context, that’s faster than the blink of a human eye. Whether you’re building a robotic arm for a competition or automating a mini conveyor belt, this servo ensures your project doesn’t just move—it dances.

From Classroom to Cutting-Edge Labs

The S51 isn’t just for tinkerers in garages. Educators use it to teach mechatronics, letting students grasp concepts like PID control and feedback loops without intimidating hardware. Startups, meanwhile, are embedding it into wearable tech prototypes. One example? A glove that translates sign language into text by tracking finger movements—powered by five S51 servos.

Even the entertainment industry has taken notice. Stop-motion animators adore its quiet operation (no louder than a whisper at 42 dB) for adjusting miniature sets without disrupting shoots. And let’s not forget drone racing enthusiasts, who rely on its precision to navigate tight corners at 60 mph.

Decoding the Datasheet: What Really Matters

While specs like "4.8V no-load current" might glaze your eyes, here’s the cheat sheet:

Stall Current (650 mA): This is the max draw under heavy load. Pair it with a battery that can handle brief spikes. Temperature Range (-30°C to +60°C): Perfect for outdoor bots, from snowplow drones to desert-roving sensors. PWM Signal Compatibility: Works seamlessly with Arduino, Raspberry Pi, and ESP32 boards.

But the unsung hero? The servo’s nylon gears. They’re durable enough for daily use but forgiving enough to prevent motor burnout during accidental collisions—a lifesaver for rookies.

Hacking the S51: Creative Projects Beyond the Basics

So you’ve mastered the basics. Now what? Let’s push boundaries. One Reddit user rigged an S51 to a sunflower-shaped solar tracker, boosting panel efficiency by 15%. Another modified it into a “cat toy launcher,” syncing with a motion sensor to fling feathers when their pet approaches. The secret sauce? The servo’s 180-degree rotation range, which allows for both subtle adjustments and dramatic sweeps.

For coders, the S51’s programmability opens wild possibilities. With Python scripts, you can sync multiple servos to create a robotic xylophone band or a kinetic art installation that reacts to music. Its 3-pin interface (power, ground, signal) means even novices can wire it up in minutes.

Troubleshooting: When Tiny Titans Misbehave

Even the best hardware has quirks. Common S51 gripes include jittery movement (often fixed by adding a capacitor to stabilize voltage) or gears slipping after a drop (a dab of thread locker solves this). The datasheet’s “idle current” spec (6 mA) is a clue for energy-conscious builds—if your robot’s battery drains overnight, check for servos left in “active” mode instead of powering down.

And yes, the S51 can overheat if pushed beyond its 1.6 kg·cm torque limit. But here’s a pro tip: glue a tiny heatsink to the motor casing, and you’ll squeeze out 10% more endurance.

The Future of Micro Servos: What’s Next?

As IoT and AI shrink, demand for compact yet robust actuators will explode. Imagine swarms of S51-like servos in nanodrones that pollinate crops or inspect disaster zones. Or medical devices where servos this small adjust insulin pumps based on real-time glucose levels.

Manufacturers are already experimenting with graphene-enhanced gears for quieter operation and carbon fiber casings to shave off another gram. Meanwhile, open-source communities are crowdsourcing “servo profiles” for plug-and-play compatibility with AI frameworks like TensorFlow Lite.

Final Spin

The micro servo 9g S51 isn’t just a component—it’s a catalyst for innovation. Whether you’re a teen building your first robot or an engineer prototyping the next Mars rover’s arm, this tiny titan proves that big ideas don’t need bulky hardware. So grab your datasheet, fire up your soldering iron, and join the revolution. The future is small, and it’s already here.