Precision in Motion: How KPOWER’s Servo Systems Redefine Control

Let’s talk about movement. Not the kind you do on a dance floor, but the kind that powers factories, robotics, and high-tech automation. Imagine a machine that moves with the exactness of a surgeon’s hand—no stutters, no guesswork. That’s where servo motors and drives come in. And if you’ve ever wondered why some systems just feel smoother, quieter, or more responsive, the answer often lies in the quality of these components.

KPOWER isn’t here to sell you buzzwords. We’re here to solve problems. Like the time a packaging plant struggled with inconsistent labeling speeds. Their old motors couldn’t keep up, leading to wasted materials and downtime. After switching to KPOWER’s servo systems? A 30% boost in efficiency—and zero label misalignments. Stories like this aren’t rare; they’re the norm when precision meets engineering.

Q: Why do industries keep coming back to servo systems?

A: Simple. They’re the Swiss Army knives of motion control. Need variable speeds? Check. High torque at low speeds? Done. Quiet operation for medical devices? Absolutely. Servo systems adapt, and KPOWER’s designs push that flexibility further.

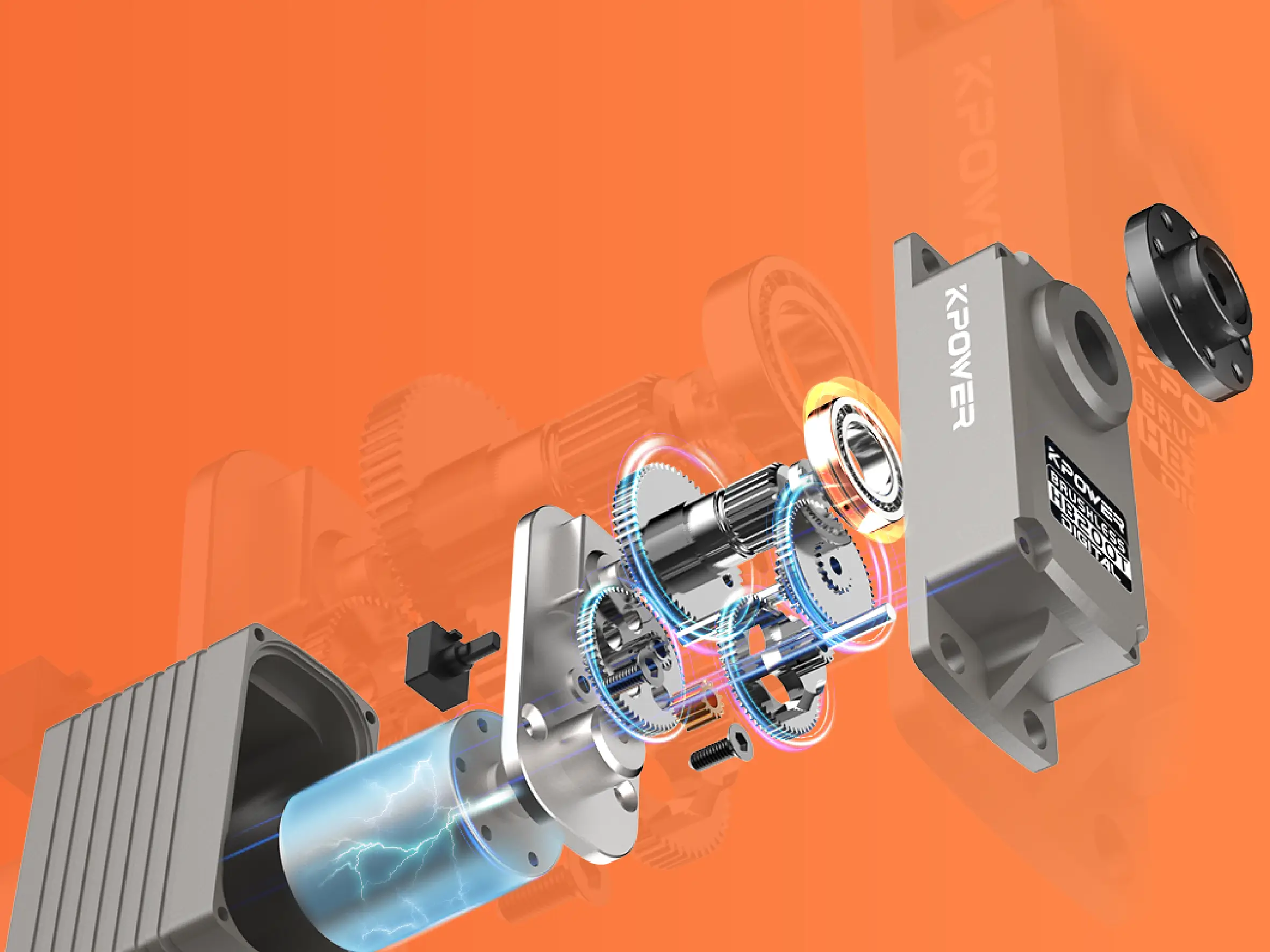

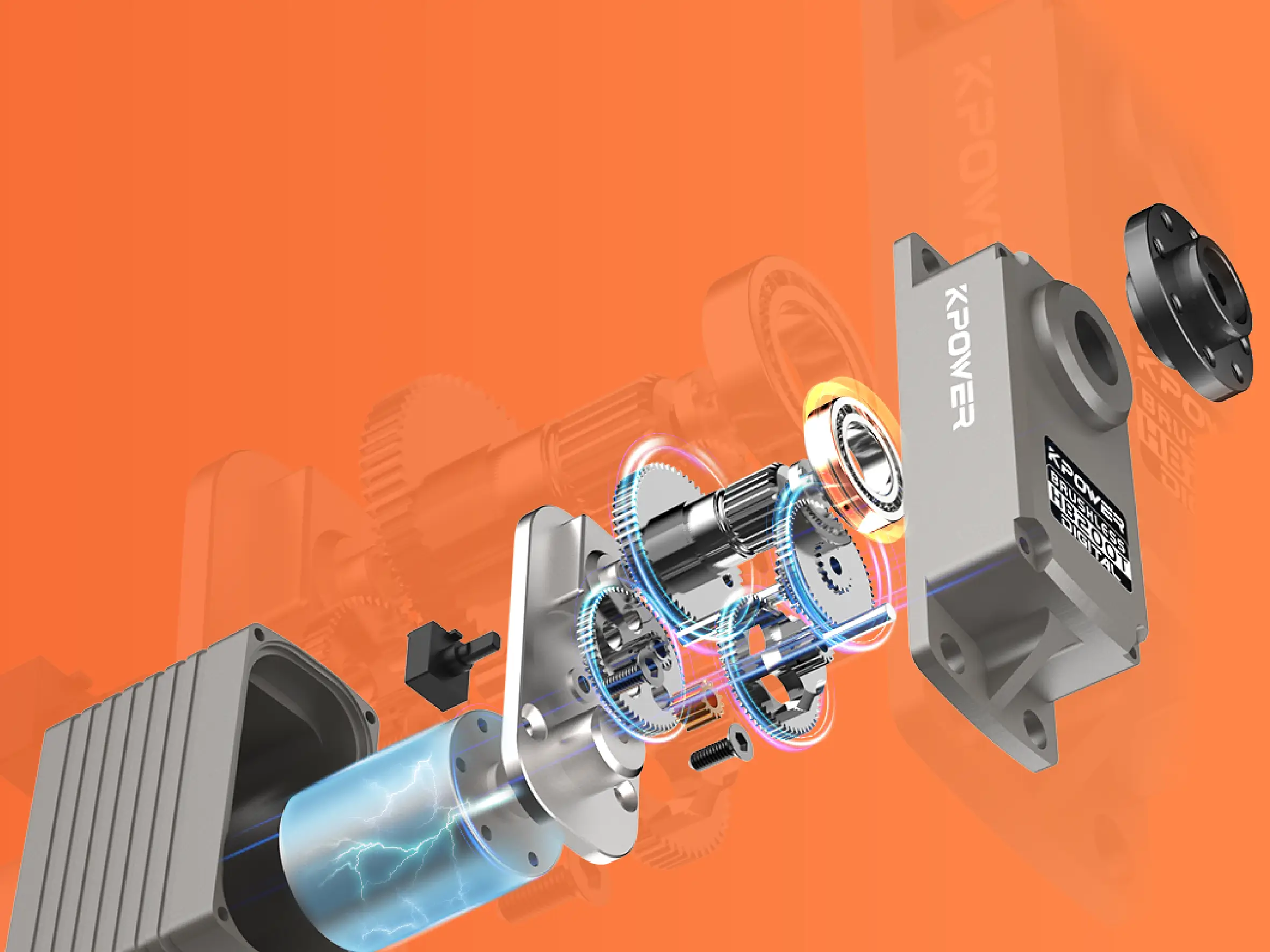

But let’s get technical for a second—without getting lost in jargon. A servo motor isn’t just a motor. It’s a loop. Sensors feed real-time data to the drive, which tweaks performance on the fly. Think of it as a conversation between components: “Hey, the load just increased.” “Got it—adjusting torque.” This dialogue happens in milliseconds, ensuring seamless operation even under stress.

What sets KPOWER apart? For starters, durability. One user joked that their KPOWER servo survived a factory environment “rough enough to make a tank blush.” Dust, vibrations, temperature swings—no match for sealed housings and shock-resistant materials. Then there’s energy efficiency. One automotive client slashed power consumption by 22% yearly, just by upgrading their drives.

Q: What makes a servo motor truly reliable?

A: It’s not about never failing. It’s about failing gracefully. KPOWER’s drives include predictive diagnostics—like a mechanic who spots engine trouble before the check-engine light flashes. Overheating? The system throttles back before damage occurs. Voltage spike? Built-in safeguards kick in.

Still, specs only tell half the story. The real magic happens in the details. Take cable management. Poorly routed cables cause interference, leading to erratic behavior. KPOWER’s plug-and-play designs minimize clutter, cutting setup time by hours. Or consider software integration. Proprietary algorithms sync with industry-standard PLCs, so retrofitting old machinery feels effortless.

Here’s the thing: motion control isn’t just about moving parts. It’s about trust. Trust that your machines won’t falter during a critical order. Trust that downtime won’t eat into profits. KPOWER builds that trust by blending cutting-edge tech with down-to-earth solutions—no fluff, no overpromises.

So, whether you’re automating a bakery or a aerospace assembly line, remember: precision isn’t a luxury. It’s the baseline. And with the right servo systems, “good enough” becomes “better than ever.”

Want to see how KPOWER’s solutions fit your needs? Let’s just say we’re good listeners. Reach out—when you’re ready.