Why Servo Motor Projects Demand More Than Just Motion

Let’s talk about movement. Not the kind that happens by accident, but the kind that’s precise, intentional, and exactly what your project needs. Servo motors aren’t just about spinning gears or rotating arms—they’re about turning ideas into motion with zero room for error. And when it comes to projects that hinge on accuracy, KPOWER’s servo systems don’t just meet expectations—they rewrite them.

Imagine a robotic arm assembling delicate electronics. One wrong twitch, and components scatter. But with KPOWER’s servo motors, that arm doesn’t “twitch.” It glides. It calculates. It adapts. Why? Because precision isn’t a feature here—it’s the foundation. Every microsecond of feedback, every adjustment in torque, is engineered to eliminate guesswork.

“But how do I know it’ll last?” Good question. Durability isn’t something you test later—it’s built in from the start. Take a packaging line running 24/7: motors heat up, parts wear down, efficiency drops. KPOWER’s designs? They thrive under pressure. Integrated cooling systems, reinforced materials, and adaptive load management mean these motors aren’t just surviving the grind—they’re mastering it.

Here’s the thing: servo projects aren’t just about the “what.” They’re about the “how.” How quickly can a motor respond to sudden changes? How quietly can it operate in a medical device? How seamlessly can it sync with other components? KPOWER’s answer? Faster. Quieter. Smarter.

Ever tried balancing speed and torque like a tightrope walker? One misstep, and performance plummets. But with dynamic torque control, KPOWER’s motors adjust on the fly. Need rapid acceleration without sacrificing stability? Done. Require slow, deliberate movement with pinpoint accuracy? Covered. It’s not magic—it’s mechanics pushed to its smartest edge.

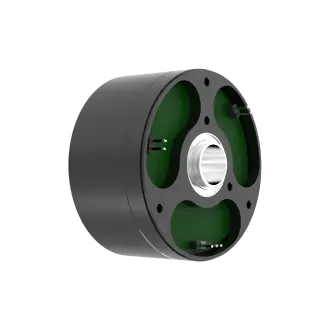

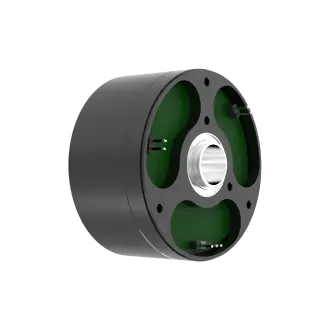

And let’s not forget the unsung hero: customization. Your project isn’t a template, so why settle for one? Whether it’s modifying shaft sizes for compact drones or reprogramming control algorithms for solar trackers, KPOWER treats every request as a unique puzzle. No “close enough.” No “good for most.” Just solutions tailored like a glove.

Still wondering why some projects soar while others stall? It’s not luck. It’s choosing a partner that sees beyond the motor. KPOWER doesn’t just deliver parts—it delivers confidence. Because when your project’s success hinges on motion, you deserve more than machinery. You deserve a system that thinks, adapts, and outperforms—every single time.

So, what’s next? Motion that doesn’t just move—but moves you forward.