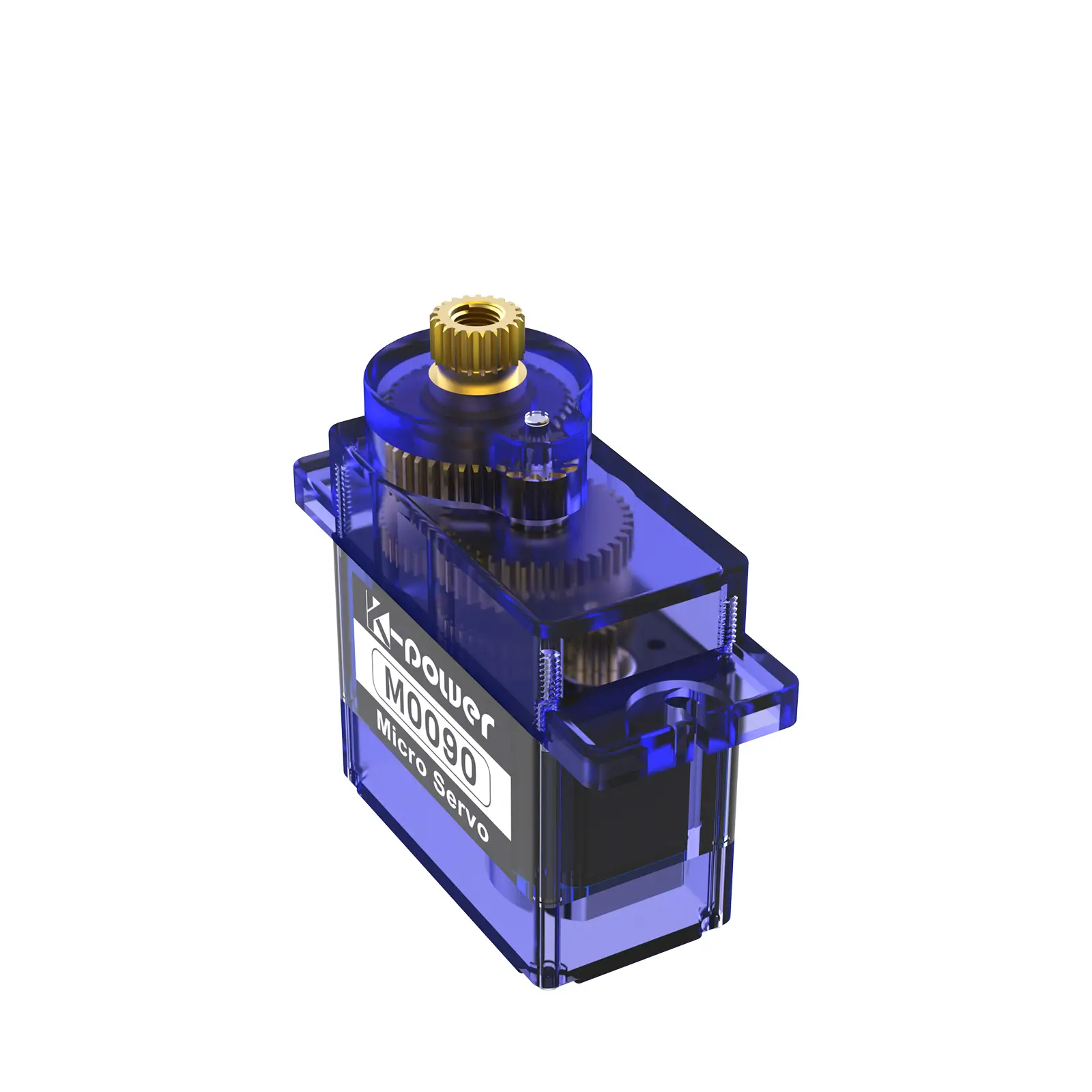

Precision in Motion: Why a 0-180 Degree Servo Motor Could Be Your Next Game-Changer

Picture this: a compact device that spins, stops, and holds position with surgical accuracy. No guesswork, no jerky movements—just smooth, reliable motion exactly where you need it. That’s the magic of a 0-180 degree servo motor. But why should you care? Let’s break it down.

The “Sweet Spot” for Control

Not every project needs a full 360-degree spin. Sometimes, half the range is twice the efficiency. A servo motor limited to 180 degrees eliminates unnecessary rotation, focusing energy on precise, repeatable movements. Think robotic arms picking components on an assembly line or automated camera rigs panning between fixed angles. It’s like having a skilled dancer who knows every step by muscle memory—no wasted motion, just flawless execution.

“But what if I need flexibility?” Great question. KPOWER’s servo motors aren’t one-trick ponies. Built-in programmable settings let you adjust speed, torque, and endpoints on the fly. Need a 90-degree sweep today and 120 tomorrow? A few tweaks in the control software, and you’re set. No hardware swaps, no downtime.

Durability Meets Quiet Power

Ever used a motor that sounds like a coffee grinder after a week? Frustrating, right? Overengineering is KPOWER’s quiet rebellion. Stainless steel gears, sealed bearings, and thermal protection ensure these motors hum along even in dusty workshops or humid environments. One user compared theirs to “a librarian who lifts weights”—powerful but whisper-quiet.

Real-World Wins

Take solar panel alignment. A farm in Arizona needed panels to tilt precisely between sunrise and sunset angles. Traditional motors burned out within months. After switching to KPOWER’s 0-180 servos? Three years and counting, with a 20% boost in energy capture. Or consider hobbyists building custom drones—these motors provide the exact tilt control needed for stable aerial shots without adding bulk.

The Support You Didn’t Know You Needed

Here’s the kicker: a great product is only half the story. KPOWER’s team obsesses over the unsexy stuff—like documentation. Every motor ships with troubleshooting guides written in plain language, not engineer-speak. Stuck at 2 AM? Their 24/7 online resource hub has video walkthroughs, wiring diagrams, and a community forum where real users swap tips.

“What about repairs?” Fair concern. Instead of forcing you to mail units back, KPOWER sends replacement parts with labeled diagrams—think IKEA instructions but actually helpful. One customer joked it’s “like they’ve pre-empted every ‘oops’ moment I’ve ever had.”

Bottom Line

A 0-180 degree servo motor isn’t just a component—it’s a decision to prioritize precision over excess, reliability over flashy specs. KPOWER’s blend of rugged hardware and no-nonsense support turns “it works” into “it works perfectly.” Whether you’re automating a factory or prototyping the next big thing in robotics, sometimes the smartest move is knowing exactly where to draw the line—0 to 180, no more, no less.

Still on the fence? Here’s a challenge: try explaining your project to their support chatbot. If it doesn’t suggest at least two optimizations you hadn’t considered, we’ll eat our hat. (Spoiler: Keep the hat. They’re that good.)