Unlock Precision Control: Your Arduino Servo Motor Solution

Imagine bringing your robotics project to life with smooth, precise movements—no jitters, no guesswork. That’s the power of pairing Arduino with a high-performance servo motor. Whether you’re crafting a robotic arm, automating a small gadget, or experimenting with interactive art, the right setup can turn complexity into simplicity. Let’s dive into how a well-designed program for servo motors using Arduino can elevate your creations.

Why Arduino? It’s About Flexibility

Arduino’s open-source platform thrives on adaptability. Need a 180-degree sweep for a pet feeder? Or micro-adjustments for a camera stabilizer? With Arduino, tweaking angles, speeds, and delays becomes intuitive. The magic lies in its library support—pre-written functions like Servo.write() or Servo.attach() let you skip tedious coding steps. But here’s the catch: not all servo motors play nice with every board. Voltage mismatches or signal noise can derail even the cleanest code.

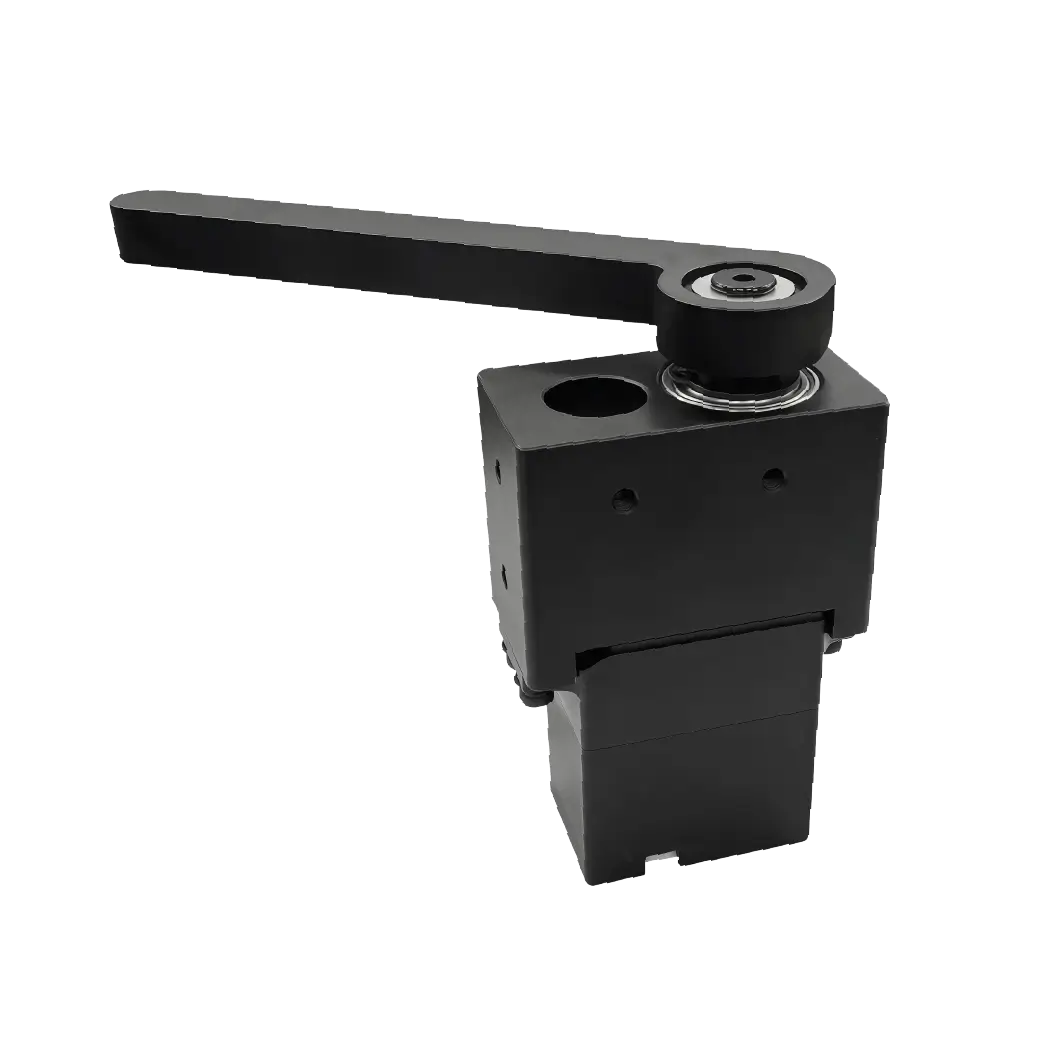

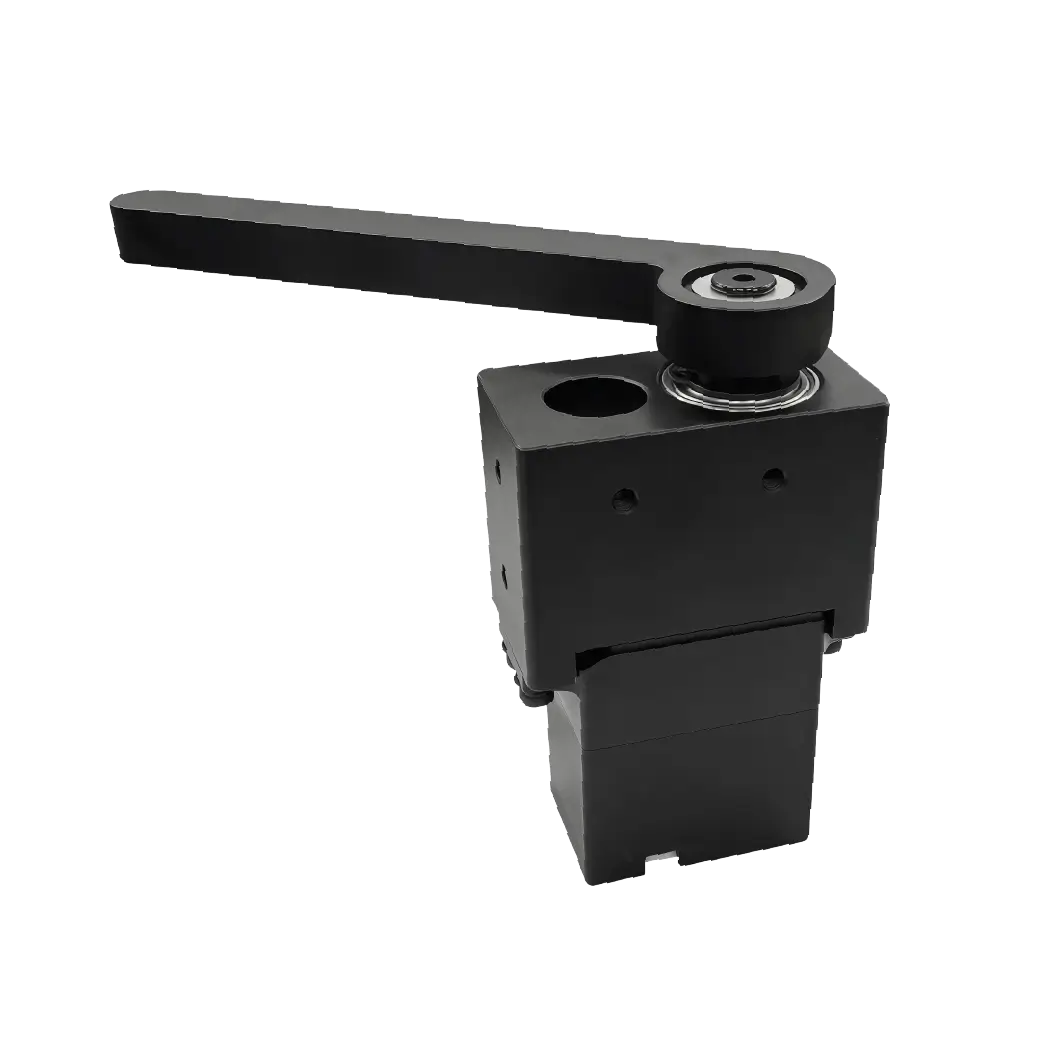

That’s where KPOWER steps in. Designed for seamless Arduino integration, KPOWER servos handle 5V logic without hiccups. Their gearboxes minimize chatter, while built-in potentiometers ensure accurate feedback. No more debugging hardware issues—just plug, program, and pivot.

Real-World Wins: From Prototype to Perfection

Take Jenna’s solar tracker project. She needed servos to adjust panel angles hourly. Initial attempts led to jerky motion and overheating. Switching to KPOWER’s servos and a streamlined Arduino sketch solved both. “The code was simple—just map sunlight sensor values to servo positions. But the motor’s smooth operation made all the difference,” she shared.

Or consider DIY hobbyist Marco, who built a servo-driven chessboard. His challenge? Coordinating eight motors simultaneously. Arduino’s multitasking capabilities, combined with KPOWER’s low-latency response, kept moves crisp. “It felt like the motors read my mind,” he laughed.

Your Questions, Answered

“How do I avoid servo burnout?”

Stick to motors with overload protection—KPOWER models include thermal cutoffs. Also, avoid overloading the Arduino’s power supply; use an external battery for high-torque tasks.

“Can I daisy-chain multiple servos?”

Yes, but manage signal timing. Arduino can handle multiple instances of the Servo library, though resource limits vary by board. For complex projects, consider a servo shield or controller.

The KPOWER Difference: Built for Makers

What sets KPOWER apart isn’t just specs—it’s reliability. Their servos come pre-calibrated, reducing setup time. Need to reverse rotation direction? A quick code flip does the trick, no hardware tweaks required. Plus, their compact design fits tight spaces, ideal for drones or wearable tech.

Still, even the best hardware needs smart programming. Start with clean code: declare servo objects, define pins, and use loops for repetitive motions. Test incrementally—validate each function before scaling up. Remember, a well-structured sketch isn’t just about functionality; it’s about future-proofing. When upgrades come, you’ll thank yourself for commenting your code.

Final Thought: Motion Made Simple

Arduino and servo motors are a match made for innovation. With KPOWER’s tailored solutions, the gap between idea and execution shrinks. No jargon, no frustration—just results that move. Ready to transform your project? The next step is yours to take.