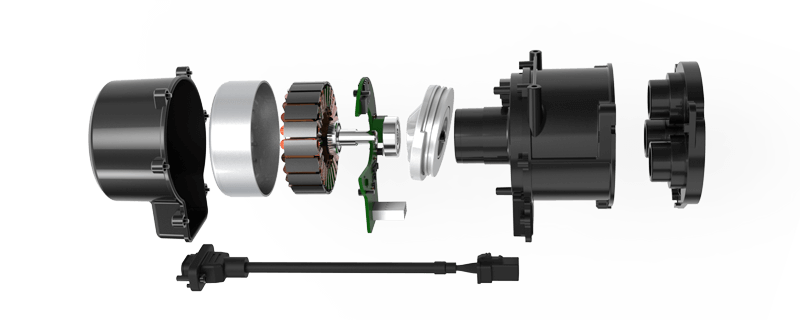

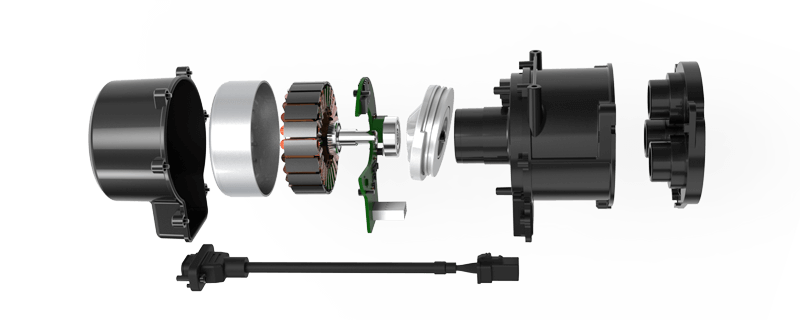

The Mechanics Behind DC Motors with Gears

When we think about motion, whether it’s a simple fan whirling or a complex robotic arm in action, the power behind these movements often comes from an electric motor. Among the various types of motors, DC motors are one of the most widely used due to their simplicity, control, and versatility. But what happens when you combine the efficiency of a DC motor with the power of a gear mechanism? This is where the magic of a DC motor with gear begins.

A DC motor is an electric motor that runs on direct current (DC) and relies on electromagnetism to generate motion. Its design allows for easy control of speed and direction, making it a staple in both industrial and consumer products. However, a standard DC motor operates at a constant speed, which isn't always ideal for all applications. That's where gears come into play.

Gears are mechanical devices used to transmit motion and torque between machine components. When attached to a DC motor, gears can modify the output speed and torque to suit the specific needs of the application. By increasing the torque or adjusting the rotational speed, gears help DC motors become more versatile in their ability to perform various tasks. The combination of these two technologies creates a motor system that can adapt to a wider range of environments and tasks.

Why Use Gears with DC Motors?

The inclusion of gears in a DC motor system offers a multitude of benefits. Here are some of the key reasons why engineers and manufacturers choose this combination for various applications:

Increased Torque:

Gears allow a DC motor to deliver higher torque at lower speeds, which is essential in tasks that require heavy lifting or pushing. In many applications, like power tools or robotics, increased torque is needed to move or manipulate larger objects. By modifying the gear ratio (the ratio between the number of teeth on the driving gear and the driven gear), engineers can ensure that the DC motor produces more power without sacrificing efficiency.

Speed Control:

While DC motors are known for their precise speed control, gears add another layer of flexibility. With a simple change in the gear ratio, a DC motor can provide variable speeds, which is crucial in machines that need to operate at different speeds for different tasks. In automotive applications, for example, gears help regulate the speed of the wheels, ensuring that the motor doesn’t overwork at higher speeds or underperform at lower speeds.

Efficiency:

One of the hallmarks of DC motors is their efficiency, and when combined with gears, they can achieve even better results. Gears allow motors to work at optimal speeds, reducing wear and tear and improving the overall lifespan of the motor. Additionally, using gears can minimize the energy loss that often occurs when motors are forced to run at inefficient speeds, which makes the entire system more energy-efficient.

Compact Design:

The compact nature of DC motors paired with gears allows manufacturers to design systems that are both powerful and small enough to fit into tight spaces. This is why you’ll find these motor-gear combinations in everything from small appliances to advanced robotic systems. The versatility of these setups is one of the reasons they are so prevalent in the modern technological landscape.

Applications of DC Motors with Gears

Now that we have a better understanding of how DC motors and gears work together, let’s explore some of the industries and applications where this combination truly shines.

Robotics:

In robotics, precision, control, and reliability are paramount. DC motors with gears play a critical role in providing robots with the ability to perform complex movements. Whether it’s a humanoid robot performing delicate tasks or an industrial robot assembling parts in a factory, the motor’s ability to deliver both speed and torque through the gear system allows for smooth, controlled actions. This makes robots more adaptable to a variety of environments, from factories to hospitals, where both strength and precision are required.

Electric Vehicles:

The automotive industry, particularly electric vehicles (EVs), has also embraced DC motors with gears. DC motors provide the high efficiency and torque required for smooth acceleration and speed control in EVs. When combined with a gear mechanism, they enable better energy conversion, longer battery life, and a more controlled driving experience. Gears also help manage the power delivery, ensuring that the motor operates optimally across a range of speeds, from city driving to highway cruising.

Power Tools:

Power tools like drills, saws, and screwdrivers also benefit from the combination of DC motors and gears. Many of these tools need to deliver high torque to perform heavy-duty tasks but also require a fine level of speed control for precision work. The gear system allows the motor to adjust to these demands, providing the necessary power without overloading the system. This leads to tools that are not only more efficient but also safer to use.

Home Appliances:

DC motors with gears are commonly found in home appliances, from washing machines to vacuum cleaners. In washing machines, for example, the motor drives the drum at different speeds depending on the wash cycle selected. Gears help the motor achieve the right balance between speed and torque, ensuring that clothes are cleaned effectively while conserving energy. In vacuum cleaners, the motor powers the fan to create suction, and the gear mechanism helps regulate the airflow for different surfaces, optimizing cleaning performance.

Aerospace and Drones:

The aerospace and drone industries require motors that are lightweight, efficient, and reliable. DC motors with gears are often used in applications such as actuators for controlling surfaces or rotating propellers. The ability to fine-tune the speed and torque of the motor through gears allows drones and other aerial vehicles to fly smoothly and with greater precision, enhancing both performance and safety.

Conclusion

DC motors with gears represent a seamless integration of two fundamental engineering principles: electric motor technology and mechanical transmission. By combining these technologies, engineers can create systems that are not only powerful and efficient but also adaptable and precise. From robotics to consumer electronics, the versatility of these systems continues to drive innovation across numerous industries. As technology evolves, we can expect to see even more applications emerge, with DC motors and gears continuing to power the devices and machines that shape our world.

Established in 2005, Kpower has been dedicated to a professional compact motion unit manufacturer, headquartered in Dongguan, Guangdong Province, China.