part 1: Unleashing Precision and Power: The Magic of the DC N20 Geared Motor

When it comes to building small-scale mechanical projects or powering compact devices, one component consistently rises to the challenge: the DC N20 geared motor. This diminutive yet mighty motor has revolutionized how hobbyists, engineers, and innovators approach design, offering a perfect blend of power, efficiency, and versatility that fits neatly into tight spaces.

What is a DC N20 Geared Motor? At its core, a DC N20 geared motor combines a simple direct current motor—often called a “brushed” motor—with an integrated gear reduction system. The term “N20” refers to the motor's size, approximately 20 millimeters in diameter—a size that makes it ideal for small robots, drones, automated toys, and precision instruments.

The gear train—often a planetary or spur gear system—serves to reduce the motor’s high rotational speeds to a more manageable and useful output. This gear reduction increases torque while lowering rotational speed, providing users with a motor that can handle heavier loads without sacrificing efficiency. This dual characteristic of high torque and controllable speed makes the N20 geared motor incredibly popular.

Design Features and Components The core of this motor is an electromagnetic coil wound around a rotor, which spins when current flows through it. Encased within a compact metal or plastic housing, the gear set sits atop the motor, directly linked to its shaft. Typically, the gear ratio can vary—from 1:3 to as high as 1:100—depending on the application needs, influencing the balance between speed and torque.

The motor's small size doesn't mean compromised performance; rather, it allows for integration into tight spaces. Its lightweight design ensures minimal impact on the overall weight of devices, an important consideration in robotics and portable gadgets. Most N20 geared motors also come with a standard shaft size—usually 3mm diameter—making them compatible with a wide variety of mounting brackets and couplings.

Advantages of Using N20 Geared Motors The popularity of the N20 geared motor stems from several inherent advantages:

Compact Size: Perfect for miniature projects, the N20 provides significant power within a tiny package. High Torque: Gear reduction amplifies torque, enabling the motor to drive heavier loads and operate smoothly under load. Adjustable Speed: By varying the voltage supplied, or adding PWM control, users can fine-tune motor speed, offering flexibility. Ease of Installation: Its standardized design makes it compatible with numerous mounting accessories and custom enclosures. Cost-Effective: Widely available and affordable, making it accessible to hobbyists and professionals alike.

Applications in Modern Technology The versatility of the N20 gear motor manifests across a spectrum of applications. Hobbyist robotics frequently leverage these motors for driving wheels, robotic arms, and conveyor belts. Educational projects utilize them to teach mechanical principles, motor control, and automation.

In the industrial sphere, compact automation systems employ N20 motors to automate small tasks, from precise positioning in laboratory equipment to miniature plug-and-play conveyor modules. The proliferation of 3D printing and DIY electronics has made these motors foundational components for custom creations.

Choosing the Right Gear Ratio and Voltage Selecting the right N20 geared motor depends on project specifics—particularly desired speed and torque. For example, a 1:3 gear ratio offers high speed with moderate torque, suitable for lightweight applications like small fans or wheels in toys.

Conversely, a 1:100 gear ratio provides slow speeds but immense torque, ideal for lifting or driving heavy loads. Voltage considerations also come into play; while most N20 motors operate between 3V and 12V, exceeding these limits can cause overheating or damage, so using a proper voltage regulator or PWM controller is advisable.

The Future of N20 Geared Motors As technology progresses, N20 gear motors continue to evolve. Innovations include brushless variants offering longer life and higher efficiency, integrated sensors for smart control, and advanced gear materials reducing noise and increasing durability.

With the rise of IoT (Internet of Things) devices, compact motors like the N20 are poised for greater integration, powering smart home gadgets, miniature drones, and autonomous systems. Their reliability, affordability, and adaptability ensure they will remain an integral part of the engineering landscape for years to come.

part 2: Unleashing Precision and Power: The Magic of the DC N20 Geared Motor (Continued)

Continuing our exploration of the N20 geared motor’s significance, let's delve into the subtleties of customization, troubleshooting, and real-life project inspiration, demonstrating how this tiny powerhouse can make a significant difference.

Customization and Variations While the standard N20 geared motor is already versatile, numerous modifications allow for optimizing performance tailored to specific applications:

Gear Ratios: Custom gear sets can be designed or selected to manipulate speed and torque further. Voltage Control: Incorporating PWM (Pulse Width Modulation) controllers enables precise speed modulation, essential for delicate tasks or smooth acceleration. Feedback Systems: Adding encoders or sensors creates a “smart” motor system capable of precise position control or speed monitoring, vital for robotics that require accuracy.

Manufacturers also offer variants with different gear materials—metal gears for higher durability and noise reduction, or plastic gears for lightweight, low-cost projects. Some N20 motors come with integrated slip rings or brushes designed for extended lifespan in demanding environments.

Troubleshooting Common Issues Despite their simplicity, N20 geared motors occasionally pose challenges. Here are common problems and their potential solutions:

Motor Not Running: Ensure the power supply voltage is within recommended limits. Check for wiring errors or loose connections. Reduced Torque or Speed: May indicate gear wear or debris in the gear train. Regular maintenance or replacement might be necessary. Overheating: Overvoltage or prolonged operation can cause overheating. Use voltage regulation, reduce load, or incorporate cooling solutions. Unusual Noise: Excess gear wear or misalignment. Upgrading to metal gears or realigning components can help.

Routine maintenance—like cleaning gear teeth, lubricating moving parts, and inspecting wiring—can significantly extend the motor’s lifespan.

Safety Considerations While the N20 gear motor is generally safe, it shouldn’t be overlooked in terms of safety protocols:

Ensure proper insulation of wiring to prevent short circuits. Use appropriate current-limiting devices to prevent overloads. Secure the motor firmly in place to prevent unintended movement.

Prototyping and Design Tips Incorporating the N20 into your projects requires thoughtful design:

Use CAD models to plan mounting brackets and gear alignments. Consider wireless or remote control interfaces for motor operation. Integrate sensors for feedback loops, enabling autonomous adjustments.

Innovative Projects Powered by the N20 Gear Motor

Miniature Robotics: Building a tiny robot that navigates obstacles or follows a line—powered by N20 motors controlling wheels or tracks. Their compact size allows for sleek designs that can fit into tight spaces.

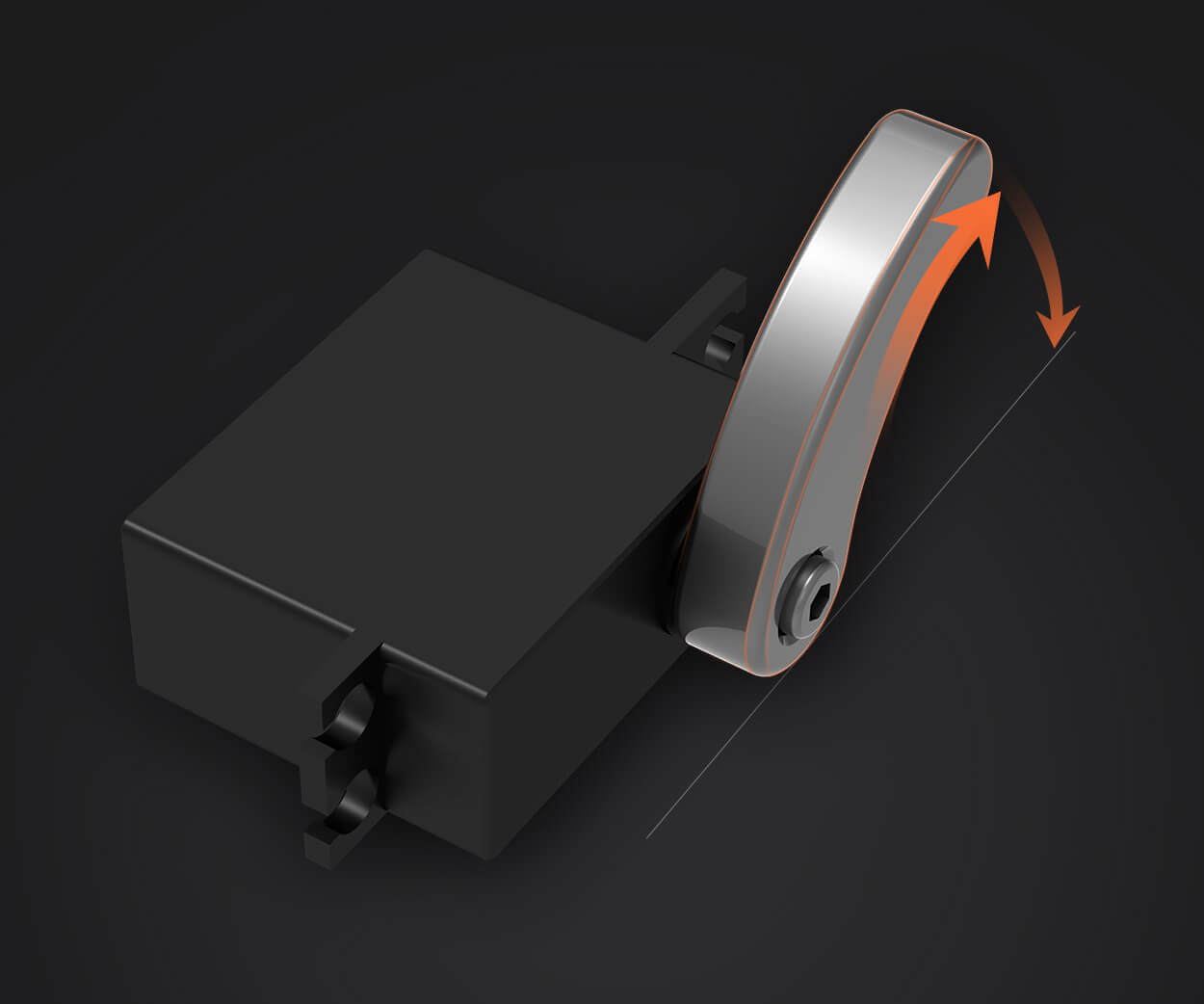

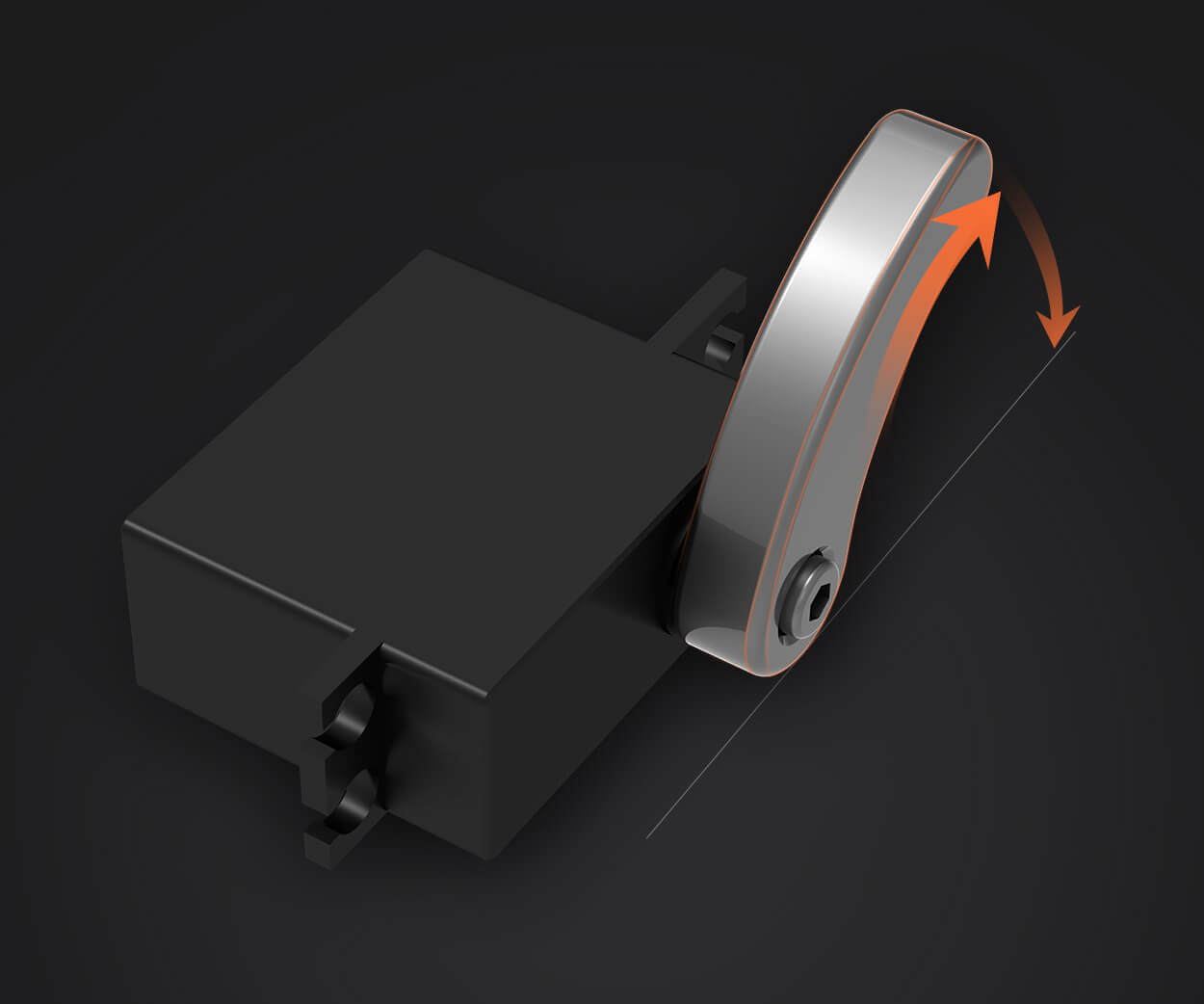

Automated Door Locks: Small mechanisms that unlock or latch doors automatically, driven by N20 motors with precise rotational control.

Camera Stabilizers: Pocket-sized gimbals that counteract hand movements, utilizing the motor's smooth control capabilities.

Educational Kits: DIY kits that teach students about electronics and mechanics, with N20 gear motors as hands-on components.

Custom 3D Printing Projects: Incorporate N20 motors into custom-designed devices—like mini conveyor belts for sorting or milling.

The Versatility of Power Sources While most N20 motors operate on standard DC batteries, experimenting with power sources can unlock unique functionalities. For example:

Rechargeable Lithium-Ion Batteries: For longer deployments and higher efficiency. Solar Panels: In outdoor applications, harnessing solar energy makes projects eco-friendly and self-sufficient. Wireless Power Transfer: Future-oriented approach—wirelessly powering gadgets with embedded N20 motors.

Conclusion: The Endless Possibilities The DC N20 geared motor exemplifies how a small component can catalyze big innovations. Its blend of size, power, and adaptability makes it a favorite across numerous fields—whether for educational purposes, experimental prototypes, or commercial products.

By understanding its mechanics, customizing gear ratios, and effectively troubleshooting, creators can elevate their projects from simple concepts to real-world solutions. As technology advances, the potential for N20 geared motors is limitless—powering the future of miniature automation, robotics, and beyond.

Harness this tiny dynamo’s promise, and let your imagination turn ideas into action with precision, power, and style.

Kpower has delivered professional drive system solutions to over 500 enterprise clients globally with products covering various fields such as Smart Home Systems, Automatic Electronics, Robotics, Precision Agriculture, Drones, and Industrial Automation.