part 1:

In the rapidly evolving realm of drone technology and aerial imaging, the role of gimbal motors is often underestimated but absolutely vital. These tiny yet mighty components are the backbone behind steady, crystal-clear footage captured from above, transforming chaotic camera shake into smooth, professional-quality visuals. Among the myriad of motor types used in gimbal systems, Brushless DC (BLDC) gimbal motors stand out as a pinnacle of engineering ingenuity, offering unmatched performance and reliability.

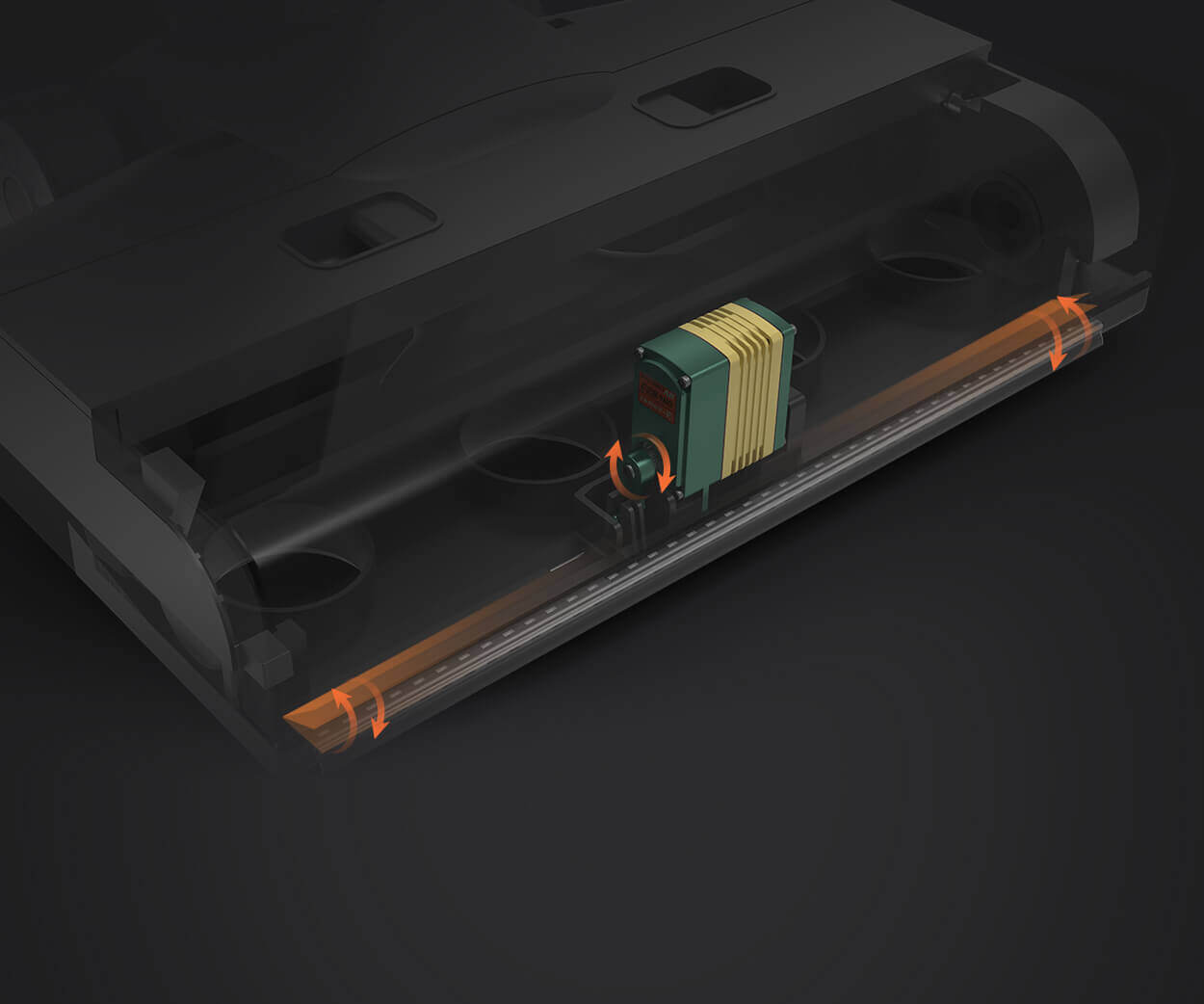

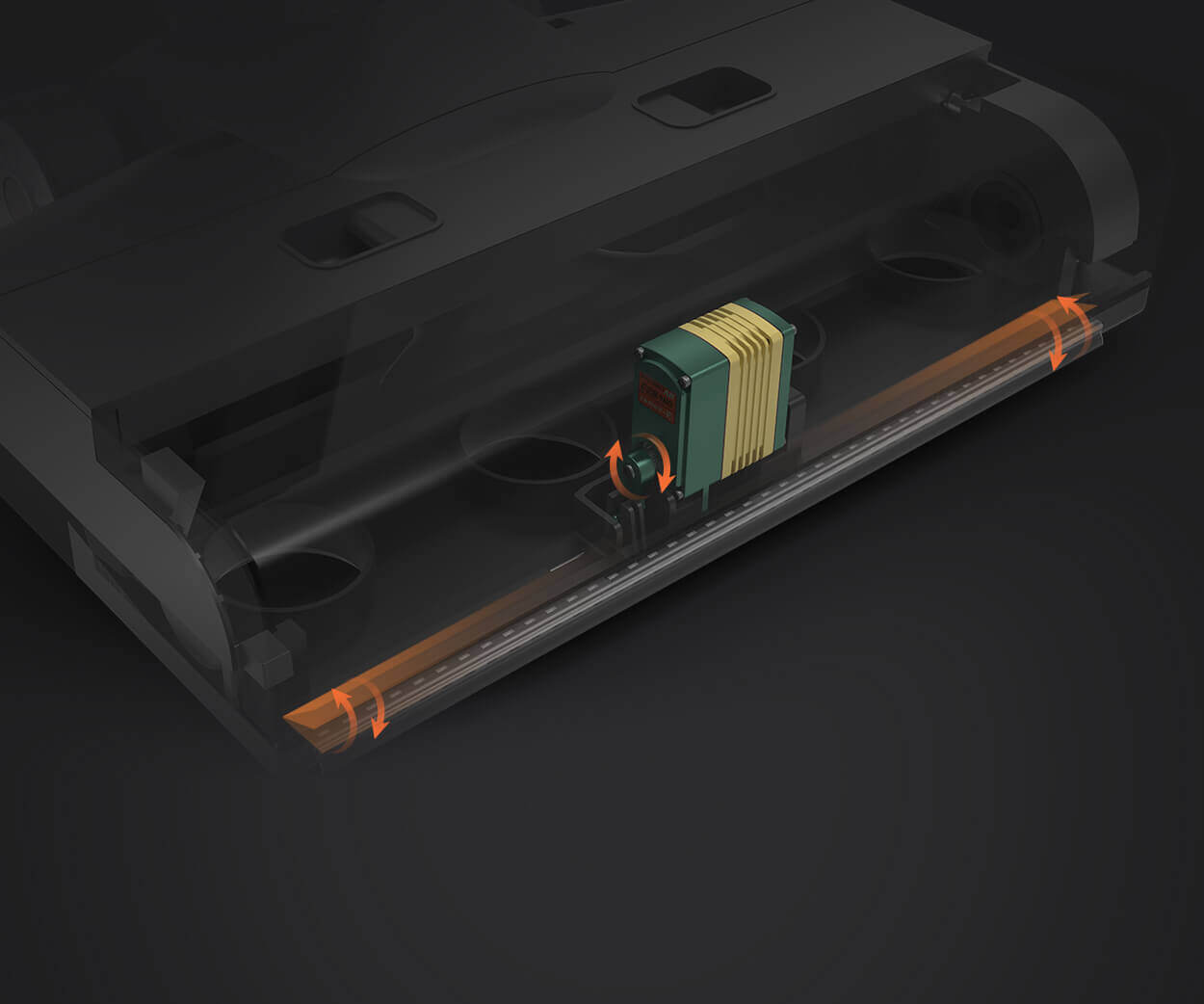

Understanding the core distinction starts with understanding what a gimbal is and why motor choice matters. A gimbal acts as a stabilization platform that keeps a camera steady regardless of drone movement, wind, or user handling imperfections. The motor’s job is to precisely rotate and counteract unwanted motion, maintaining an unwavering horizon line or targeted focus point.

The Rise of BLDC Gimbal Motors

BLDC motors have gained immense popularity in drone applications mainly due to their efficiency, compactness, and durability. Unlike traditional brushed motors, BLDC motors lack brushes to commutate their coils, reducing wear and tear while providing a smoother, more consistent performance. This durability makes them highly suitable for prolonged operation in challenging conditions—think high-altitude flights or windy environments where reliability is paramount.

Their design allows for higher torque-to-weight ratios, meaning they can generate strong stabilization forces without adding unnecessary bulk or weight—crucial factors for aerial photography where every gram counts. Moreover, BLDC motors are known for their excellent rotor inertia characteristics, translating into swift reaction times to sudden movements. This capacity for rapid adjustment is essential for maintaining stable footage when the drone encounters turbulent air or quick directional changes.

Comparing BLDC Gimbal Motors with Other Types

When juxtaposed with other common motor types used in gimbal systems, the advantages of BLDC motors become even more apparent. Let's explore some alternatives and see how they stack up:

Servo motors: Traditional servo motors are often used in hobbyist gimbals. While they are simple and inexpensive, they tend to have limited responsiveness and lower durability. The metal gears and brushes in standard servos wear out quickly under constant operation, leading to maintenance headaches.

Stepper motors: These provide precise positional control, making them suitable in some specialized gimbal setups. However, they are generally bulkier and generate more heat. Their stepwise motion can sometimes introduce jitter or vibrations, which compromise footage quality.

Brushed DC motors: The classic DC motors with brushes are less common in high-end gBM systems because they suffer from electrical wear, noise, and less efficiency. Over time, brushes degrade, and maintenance becomes inevitable, especially in prolonged flights or intense conditions.

In contrast, BLDC gimbal motors excel in many aspects:

Efficiency and Battery Life: Their brushless construction consumes less power, extending drone flight times and allowing for longer shooting sessions.

Smoothness and Responsiveness: The high-quality electronics governing BLDC motors deliver more precise and rapid adjustments—translating into jitter-free footage.

Longevity and Reliability: Without brushes that wear out, these motors are more durable, reducing downtime and maintenance.

Size and Weight: Compact and lightweight, BLDC gimbal motors are ideal for drones where payload capacity is critical.

Technical Features that Make BLDC Gimbal Motors Stand Out

Several technical characteristics attribute to the superior performance of BLDC gimbal motors:

Sensorless or sensored designs: Many BLDC motors come with sensors for accurate rotor position detection, thereby improving smoothness and stability, especially during low-speed maneuvers.

High pole counts: Higher pole counts allow for finer control and faster response times, vital for capturing stable footage in real-time.

Advanced motor controllers: Modern BLDC gimbal systems utilize sophisticated electronic controllers that optimize power delivery, improve response accuracy, and minimize vibrations during rapid movements.

Practical Applications and Real-World Impact

The real-world benefits of BLDC gimbal motors are evident in professional filmmaking, survey mapping, industrial inspections, and even hobbyist drone flying. For filmmakers, every fraction of a second counts; the crisp, steady shots enabled by these motors elevate production quality to near-cinematic levels.

In mapping or surveying, the precision of BLDC gimbal motors permits the creation of detailed aerial maps with minimal distortions. In industrial environments, their robustness ensures operation despite dust, debris, or harsh weather, delivering consistent results that save time and resources.

As drone technology continues to advance, so too does the complexity of gimbal systems. The integration of brushless motors with intelligent stabilization algorithms is creating a new standard of performance—making formerly complex shots now achievable with ease.

Stay tuned for Part 2, where we’ll dive deeper into advanced innovations, the future landscape of gimbal motor technology, and how to choose the right setup for your specific needs.

Leveraging innovations in modular drive technology, Kpower integrates high-performance motors, precision reducers, and multi-protocol control systems to provide efficient and customized smart drive system solutions.